This page reveals JINFAN Plate Heat Exchanger’s latest updates and industry insights.

Plate heat exchangers, as a commonly used heat exchange equipment in our daily lives, have a strong heat exchange effect and good heat exchange efficiency. JINFAN offers a wide range of products including gasketed plate heat exchangers, brazed heat exchangers, and welded heat exchangers, & PHE spare parts. Our high-efficiency heat transfer products can withstand extreme operating temperatures and pressures, contributing to longer-lasting and smaller carbon footprint solutions. We have provided products and services to more than 8,000 customers for over 35 years.

The diagnosis and troubleshooting methods for common leakage failures of plate heat exchangers cover a variety of technical means such as preliminary observation, pressure testing...

Read more

Discover common causes of plate heat exchanger leaks and get expert solutions with JINFAN heat exchanger gaskets, plates, and equipment to reduce risks and extend lifespan.

Read more

Working principle Titanium plate heat exchanger is a heat exchange device composed of multiple titanium metal plates, which realizes heat exchange between cold and hot fluids through the flow channels between plates. Titanium material exhibits excel...

Read more

Plate heat exchanger is an energy-efficient heat exchange equipment. It is widely used in food, chemical, power, HVAC and other industries with its high efficiency and compactness. Regular maintenance and care are essential to ensure its long-te...

Read more

Plate evaporator is a kind of equipment that uses high-efficiency heat exchange plates to evaporate and concentrate the medium continuously. Compared with traditional shell and tube evaporator, it has significant advantages such as compact structure,...

Read more

A Heat Exchanger is equipment used to transfer heat between two or more fluids. During operation, one fluid releases heat and the other fluid absorbs heat. This process can be various combinations such as water-water, water-oil, water-steam, gas-liqu...

Read more

Due to easy maintenance and cleaning, compact designs and heat exchange efficiency, stainless steel plate heat exchangers are widely used in sanitary applications such as food, beverage, pharmaceuticals, etc. In the production process of orange...

Read more

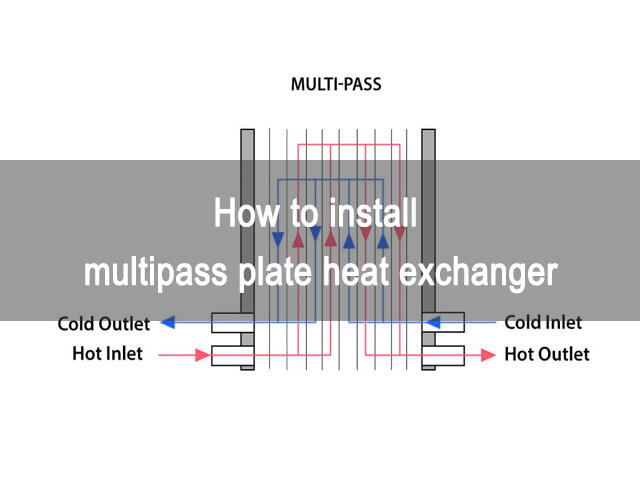

The multipass plate heat exchanger is a type of plate heat exchanger. It is designed to allow the fluid to pass through the heat exchanger multiple times before flowing out, increasing the thermal length within the same module, thereby improving hea...

Read more

In a glycol plate heat exchanger, two fluids (a mixture of glycol and water on one side and water, air, etc. on the other) transfer heat between metal plates. Heat exchangers usually comprise a series of stainless steel or other metal plates with str...

Read more

As ships continue to evolve to meet increasing environmental and performance standards, the demand for advanced equipment that can deliver reliable thermal management has never been higher. Plate Heat Exchangers (PHEs) have emerged as a superior solu...

Read more

An alkaline electrolyzer (also known as an alkaline water electrolysis (AWE) system) is a type of electrochemical device used to split water into hydrogen (H₂) and oxygen (O₂) through electrolysis in an alkaline electrolyte solution. This technology ...

Read more

Plate Heat Exchanger knowledge ( working, design, selection guide, uses, application, etc. ) sharing by JINFAN. Update regularly to keep information up to date.

Read more