Comment choisir des échangeurs thermiques à plaques pour votre application marine ? JINFAN possède des années d'expérience avec les pétroliers, les navires GNL, les porte-conteneurs, les transporteurs automobiles, etc.

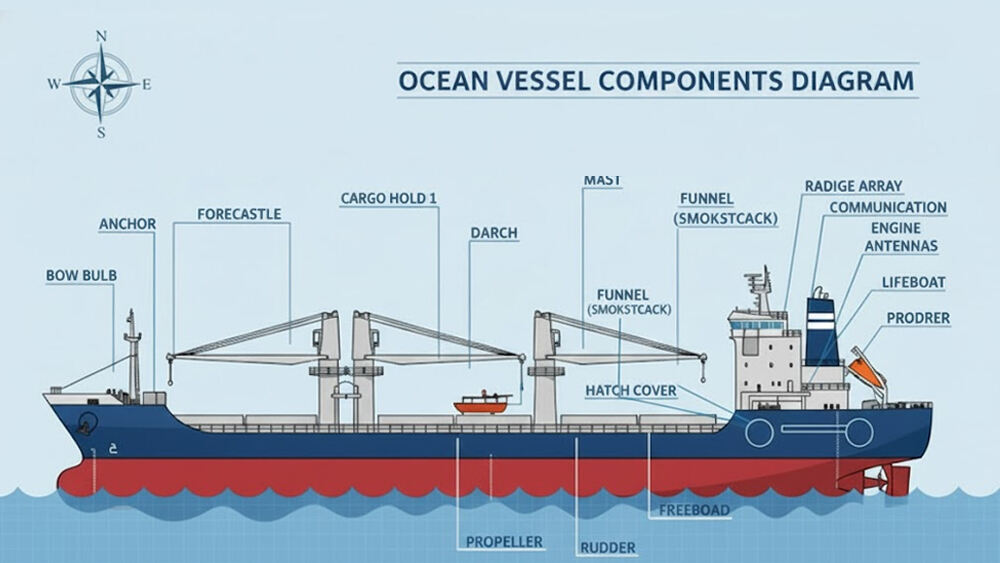

Le transport maritime est le mode de transport le plus important dans la logistique internationale, une industrie de services qui utilise des navires pour transporter des marchandises ou des passagers entre des ports situés dans différents pays et régions via des routes maritimes. Par rapport au transport aérien et terrestre, le transport maritime présente des avantages tels qu'une grande capacité, une haute flexibilité et un coût plus faible, ce qui le rend particulièrement adapté au transport de grandes quantités de marchandises sur de longues distances, bien qu'il nécessite davantage de temps. Le secteur maritime fait également face à des défis importants ; la mise en œuvre de l'indice d'efficacité énergétique (EEXI) et de l'indice d'intensité carbone (CII) oblige les compagnies maritimes à prendre des mesures afin d'améliorer l'efficacité énergétique ou de réduire la vitesse de navigation. Les échangeurs thermiques à plaques (PHE), grâce à leur efficacité élevée, leur compacité et leur flexibilité, sont devenus l'un des équipements clés permettant au secteur maritime de réaliser des économies d'énergie, de protéger l'environnement et d'améliorer la fiabilité opérationnelle.

Échangeurs de chaleur à plaques permet à deux fluides à des températures différentes d'échanger de la chaleur sans se mélanger grâce à une plaque PHE unique. Les plaques ondulées des échangeurs de chaleur sont assemblées entre un cadre et des plaques de pression, avec des joints placés dans les rainures des plaques pour assurer l'étanchéité. L'écoulement à contre-courant des fluides est fluide, et les plaques minces ainsi que la structure ondulée créent des canaux fluides très turbulents et à haute efficacité de transfert thermique, permettant un échange de chaleur maximal entre les deux fluides dans un volume minimal.

À bord des navires, les échangeurs de chaleur à plaques sont des composants essentiels de divers systèmes de refroidissement et de chauffage, garantissant le fonctionnement normal des machines et des systèmes environnementaux du navire.

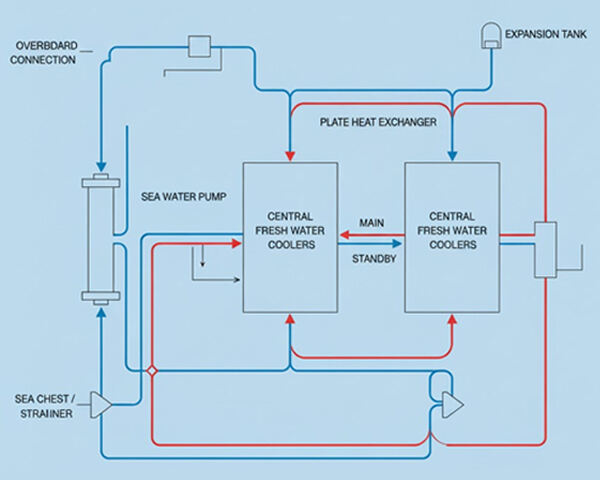

Les échangeurs de chaleur à plaques agissent comme des refroidisseurs centraux (générateur d'eau douce/refroidisseur central), utilisant l'eau de mer pour refroidir l'eau douce en circulation à bord du navire.

Refroidir l'eau de la chemise du cylindre du moteur diesel principal et du générateur ; Refroidir l'huile lubrifiante et le HFO des moteurs principaux et auxiliaires ; Refroidir l'huile hydraulique.

Les échangeurs thermiques à plaques utilisent la vapeur ou l'eau chaude résiduelle pour chauffer le fioul ; Évaporer l'eau de mer afin de produire l'eau douce requise ; Récupérer l'énergie calorifique des gaz d'échappement, améliorant ainsi l'efficacité énergétique du navire.

Les systèmes de refroidissement traditionnels à bord des navires utilisent généralement l'eau de mer pour refroidir directement tous les équipements. Toutefois, la forte salinité de l'eau de mer, son caractère corrosif et sa propension à favoriser le développement d'organismes marins entraînent l'encrassement et le colmatage des conduites et des échangeurs de chaleur. L'utilisation d'échangeurs de chaleur à plaques permet de séparer l'eau douce à haute température de l'eau de mer à basse température, en transférant efficacement la chaleur du côté eau douce vers le côté eau de mer. L'ajout d'inhibiteurs de corrosion et d'entartrage protège les systèmes de refroidissement et les canalisations des équipements critiques. L'eau douce refroidie est renvoyée vers les équipements du navire pour un refroidissement supplémentaire, tandis que l'eau de mer réchauffée est rejetée à l'extérieur. La structure démontable des échangeurs à plaques permet une maintenance simple et rapide, réduisant ainsi les temps d'arrêt.

Contactez-nous

Les échangeurs de chaleur à plaques semi-soudés JINFAN marine sont conçus pour supporter une large gamme de températures et de fluides. Les PHEs semi-soudés sont robustement construits pour résister aux vibrations et aux cycles de pression, garantissant une durabilité exceptionnelle. Disponibles en différentes tailles, ils répondent à une large gamme de capacités de transfert de chaleur et de débits, minutieusement conçus pour offrir des performances optimales. De plus, le côté du fluide de refroidissement ou de l'eau de mer peut être entièrement accessible sans déconnecter l'échangeur de chaleur semi-soudé du système de tuyauterie.

✅ La conception en plaques permet un transfert de chaleur efficace, assurant une régulation adéquate de la température ainsi qu'un confort optimal pour les passagers et l'équipage.

✅ Permet un refroidissement efficace des zones de stockage, des chambres froides et des installations de transformation des aliments à bord.

✅ Les capacités de transfert thermique efficaces des échangeurs de chaleur à plaques contribuent à l'efficacité et à la fiabilité globales des moteurs marins.

✅ Faciliter le processus de dessalement en transférant la chaleur entre l'eau de mer et l'eau douce, la rendant propre à la consommation.

✅ La chaleur récupérée peut être utilisée à diverses fins, notamment le chauffage ou la production d'électricité, ce qui contribue à l'efficacité énergétique globale du navire et réduit la consommation de carburant.

✅ Maintenir la température souhaitée en transférant la chaleur entre l'eau de ballast et le fluide de refroidissement, garantissant ainsi le respect de la réglementation environnementale.

JINFAN propose des échangeurs thermiques à plaques fiables, compacts et efficaces, faciles à entretenir et à réparer. Grâce à des solutions fiables, notre ECP peut être largement utilisé sur des yachts de luxe, d'immenses porte-conteneurs, des pétroliers géants et des plates-formes offshore. Nous utilisons des plaques en titane de haute qualité, ce qui rend l'équipement nettement plus durable, avec des performances ininterrompues dans les applications de refroidissement par eau de mer corrosive. JINFAN propose des solutions pour optimiser les systèmes thermiques à bord des plates-formes et des navires grâce à une vaste gamme d'échangeurs de chaleur à plaques.

Nous contacter

Démontable pour un entretien et une inspection faciles. Nous proposons des centaines de types de plaques, plusieurs matériaux et plusieurs modèles de joints.

Spécialement conçu pour les procédés de changement de phase tels que la condensation de vapeur, il permet un rendement énergétique extrêmement élevé.

Idéal pour les milieux à haute pression et corrosifs. Nous disposons de diverses spécifications de faisceaux soudés de plaques.

Sans joints, le risque de fuite est éliminé. Il est largement utilisé dans les conditions de température, de pression les plus élevées et en présence de substances fortement corrosives.