Entdecken Sie effiziente Wärmeübertragungslösungen für HLK-Systeme, erhalten Sie Produktauswahl, technische Unterstützung und Fallstudien, um die Leistung Ihres Systems sofort zu verbessern!

HLK (Heizung, Lüftung und Klimaanlage) ist ein Kernsystem in modernen Gebäuden und dafür verantwortlich, die gewünschte Innentemperatur, Belüftung und Luftqualität zu erreichen. Angesichts steigender Energieeffizienzstandards bei Gebäuden entwickeln sich HLK-Systeme hin zu höherer Effizienz, Energieeinsparung, Intelligenz und Umweltfreundlichkeit. Herkömmliche Rohrbündelwärmetauscher werden zunehmend durch kompaktere und effizientere Plattenwärmetauscher (PHEs) ersetzt.

Kontaktieren Sie unsPlattenwärmetauscher, bestehend aus dünnen Metallplatten mit großer Oberfläche und hervorragender Wärmeleitfähigkeit, erzeugen zwischen den Platten abwechselnde Strömungspfade für heiße und kalte Flüssigkeiten, vermeiden direkten Kontakt und ermöglichen so einen effizienten Wärmeaustausch und eine sichere Trennung. Die gewellte Oberfläche der Platten erzeugt eine turbulente Strömung, wodurch die Wärmeübergangskoeffizienten deutlich verbessert werden. Die Anzahl der Platten kann je nach Systemlast angepasst werden, um flexibel auf wechselnde Betriebsbedingungen reagieren zu können. Das Design des Plattenwärmetauschers fördert die schnelle Abfuhr von höherer Temperatur an die kalte Flüssigkeit und gewährleistet somit einen effizienten Wärmetransport. Hier klicken, um mehr über die Anwendung von Plattenwärmetauschern zu erfahren!

1. Wärme/Kälteübertragung

Durch effizienten Wärmetransport ermöglichen Plattenwärmetauscher eine schnelle, stabile und steuerbare Verteilung von Kühl- und Heizenergie und sorgen so für eine hohe Gesamtsystemeffizienz:

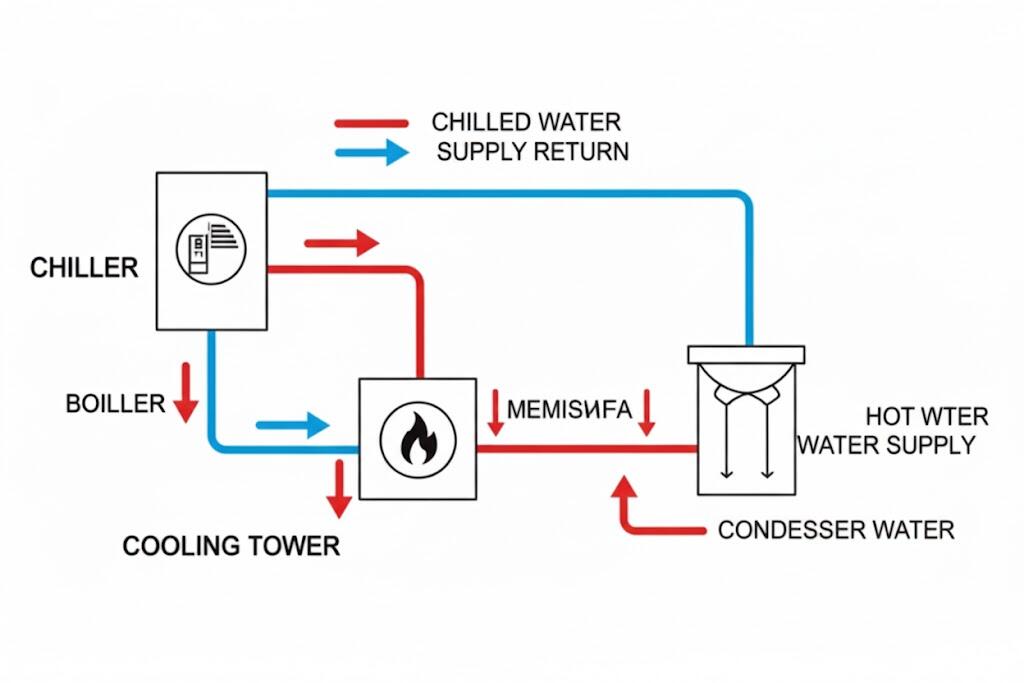

✅ Kaltwassersysteme: Ermöglichen den Kühlungsaustausch zwischen der Hauptanlage und dem Nutzer, wodurch Energieverluste reduziert werden.

✅ Heizsysteme: Übertragen Wärme effizient auf die Endgeräte innerhalb von Kesseln oder Fernwärmenetzen.

2. Systemtrennung

Klima- und Heizungssysteme enthalten häufig Kreisläufe mit unterschiedlichen Drücken und Medien. Plattenwärmetauscher wirken als Trennbarriere zwischen den Medien und ermöglichen:

✅ Die Trennung der Wasserqualität zwischen der Hauptanlage und den Nutzersystemen, um Korrosion und Ablagerungen zu verhindern.

✅ Drucktrennung zwischen Systemen mit unterschiedlichem Druckniveau zum Schutz der Hauptgeräte.

✅ Die Trennung der zentralen Kältestation vom internen Umlaufwasser des Gebäudes, was eine einfachere Zonensteuerung und Wartung ermöglicht.

3. Energieeinsparung und Kostenoptimierung

Plattenwärmetauscher zeichnen sich durch hervorragende Wärmeübertragungseffizienz aus und reduzieren den Energieverbrauch der Systeme erheblich:

✅ Verringerung der Kühllast der Kältemaschine und damit Senkung der Energiekosten;

✅ Optimierung der Energierückgewinnung, beispielsweise durch Nutzung von Abwärme zum Nachheizen oder Vorheizen.

✅ Geringer Platzbedarf und einfache Wartung senken die Investitions- und Betriebskosten.

| TYP | Typischer Aufbau | Haupt-HVAC-Anwendungen | Druck-/Temperaturbereich | Wartbarkeit | Dichtung / Leckagebeständigkeit | Kosten |

|---|---|---|---|---|---|---|

| Gedichtet | Mit Dichtungen ausgeführt, wartbar (demontierbar) | Kaltwasser, Heizungswasser, Trinkwarmwasser | ≤ 2,5 MPa / ≤ 150 °C | ⭐⭐⭐⭐ Einfach zu warten | ⭐⭐ Mäßig | Niedrig |

| Halbgeschweißt | Einseitig verschweißt, andererseits mit Dichtungen | Sole-/Glykolsysteme, Kältemittelabscheidung, Wärmepumpenkreisläufe | ≤ 3,0 MPa / ≤ 180 °C | ⭐⭐⭐ Mittelmäßig | ⭐⭐⭐ Gute | Mittel |

| Block / Vollverschweißt | Vollverschweißter Plattenstapel (keine Dichtungen) | Hochtemperaturheizung, Dampf, Wärmerückgewinnung | ≤ 5,0 MPa / ≤ 400 °C | ⭐ Geringe Wartungsintervalle | ⭐⭐⭐⭐ Sehr hoch | Hoch |

Unser Plattenwärmetauscher für die Klima- und Heiztechnik eignet sich für die anspruchsvollen Bedingungen in Fernwärme- und Fernkältesystemen. Die Fernwärme- und Fernkälteversorgung zeichnet sich als der bequemste Ansatz zur Erzeugung und Verteilung von Kälte in gewerblichen Anwendungen aus und bietet sowohl ökologische als auch wirtschaftliche Vorteile. Berechnungen zeigen, dass Kunden, die auf Fernkälte umstellen, ihre Betriebskosten im Vergleich zum Einsatz von Kaltwassersätzen in kleinen Einzelsystemen um bis zu 45 Prozent senken können. Dazu gehören erhebliche Einsparungen bei Strom, Service und Reparaturen.

Mehr erfahrenViele HVAC-Anwendungen verlassen sich auf plattierte Wärmetauscher mit Dichtungen für Kühlsysteme, Klimaanlagen und Wärmerückgewinnungssysteme.

Mehr erfahren

Kühlsysteme in verschiedenen öffentlichen Orten (wie Einkaufszentren, Bürokomplexen, Sportarenen, Eislaufbahnen) erfordern in der Regel die Beteiligung von plattierten Wärmetauschern. Unser Ziel ist es, zu reduzieren, wiederzuverwenden und zu recyceln!

Abnehmbar für eine einfache Wartung und Inspektion. Wir bieten Hunderte von Plattenarten, verschiedene Materialien und mehrere Dichtungsmodelle an.

Ideal für Hochdruck- und korrosive Medien. Wir verfügen über verschiedene Spezifikationen geschweißter Plattenpakete.

Ohne Dichtungen entfällt das Risiko von Leckagen. Es wird häufig bei höchsten Temperaturen, Drücken und starker Korrosivität eingesetzt.