Leakage of plate heat exchangers is a common operating failure that may cause media mixing, reduced energy efficiency, or even system shutdown. In order to help users quickly and accurately identify and solve leakage problems, JINFAN provides the following detailed diagnostic steps and method guidance.

During the operation of the plate heat exchanger, once there is a phenomenon such as medium mixing, reduced efficiency, or safety alarm, a simple and intuitive troubleshooting should be carried out as soon as possible:

✅ Check whether there are obvious signs of leakage (water stains, oil stains, salt crystals, etc.) on the equipment casing, joints, and ground.

✅ Observe the color, odor, corrosiveness, or sediment of the leaking medium to assist in determining the type and risk level of the leaking medium.

✅ Pay attention to whether there is expansion, deformation, or overflow in the gasket compression area.

✅ If the system pressure drops slowly or suddenly during operation, it may indicate that there is a micro-leakage or cross-plate liquid inside.

✅ For working conditions that require constant pressure operation (such as steam or refrigerant), abnormal pressure drop is a crucial precursor to leakage.

✅ The outlet temperature is lower than expected, which may be caused by the mixing of cold and hot media.

✅ The inlet and outlet temperature difference is reduced or the heat transfer efficiency is abnormal, or internal leakage affects the heat exchange performance.

When the initial observation cannot clarify the problem or there is a risk of leakage, the following systematic diagnostic methods can be used.

a. Hydrostatic test

✅ Inject water into the equipment to the set test pressure (usually 1.25 times the design pressure).

✅ Observe whether the pressure continues to drop and whether there is an external leakage point.

✅ It can be carried out in cold or hot state (operating temperature) to simulate the actual operating environment.

b. Pneumatic Test

✅ Use compressed air or nitrogen to pressurize the equipment, which is more suitable for detecting small leaks.

✅ High sensitivity, but strict safety requirements, need to stay away from the equipment and set a pressure protection valve to prevent explosion.

c. Local isolation test

✅ If it is not possible to confirm which area is leaking, you can pressurize some channels or board fragments in sections.

✅ Gradually narrow the scope of investigation and quickly locate the faulty board group.

a. Fluorescent tracer method

✅ Add a special fluorescent agent to the fluid on one side, and use an ultraviolet flashlight or detector to check whether there is penetration on the other side after running.

✅ High sensitivity, suitable for detecting small leaks or cross-flow between boards.

b. Dye tracer method

✅ Add easily dyed liquid (such as methyl blue, red oil, etc.) and observe directly with the naked eye whether there is any dyeing substance seeping out.

✅ Simple and easy to operate, suitable for primary on-site inspection.

✅ Use ultrasonic detector or acoustic sensor to monitor whether there are abnormal bubble bursts, water flow penetration and other acoustic wave signals inside the equipment.

✅ Especially suitable for internal leakage caused by tiny cracks or perforations between plates.

✅ Usually suitable for static test environment to improve the background noise isolation effect.

✅ Use infrared thermal imager to scan the surface temperature distribution of the heat exchanger;

✅ If there are local hot spots/cold spots, abnormal thermal trajectories, etc., it may indicate the mixing of cold and hot fluids caused by internal leakage;

✅ Applicable to heat exchange conditions between high temperature and low temperature media (such as steam-cold water, hot oil-refrigerant, etc.).

If the above methods still cannot accurately determine the leakage location, it is recommended to disassemble the equipment and inspect it piece by piece. Common fault characteristics include:

a. Plate problem:

✅ Cracks, perforations, pitting corrosion and other defects.

✅ Some metal plates are prone to stress fatigue cracking under high temperature or corrosive conditions.

b. Sealing gasket problem

✅ Gaskets are aged, detached, and misaligned;

✅ Incompatibility between the material and the medium leads to swelling or hardening, and the sealing performance is reduced.

c. Assembly problem

✅ The plates have problems such as misaligned assembly, insufficient clamping force, and loose fastening bolts, resulting in poor overall sealing.

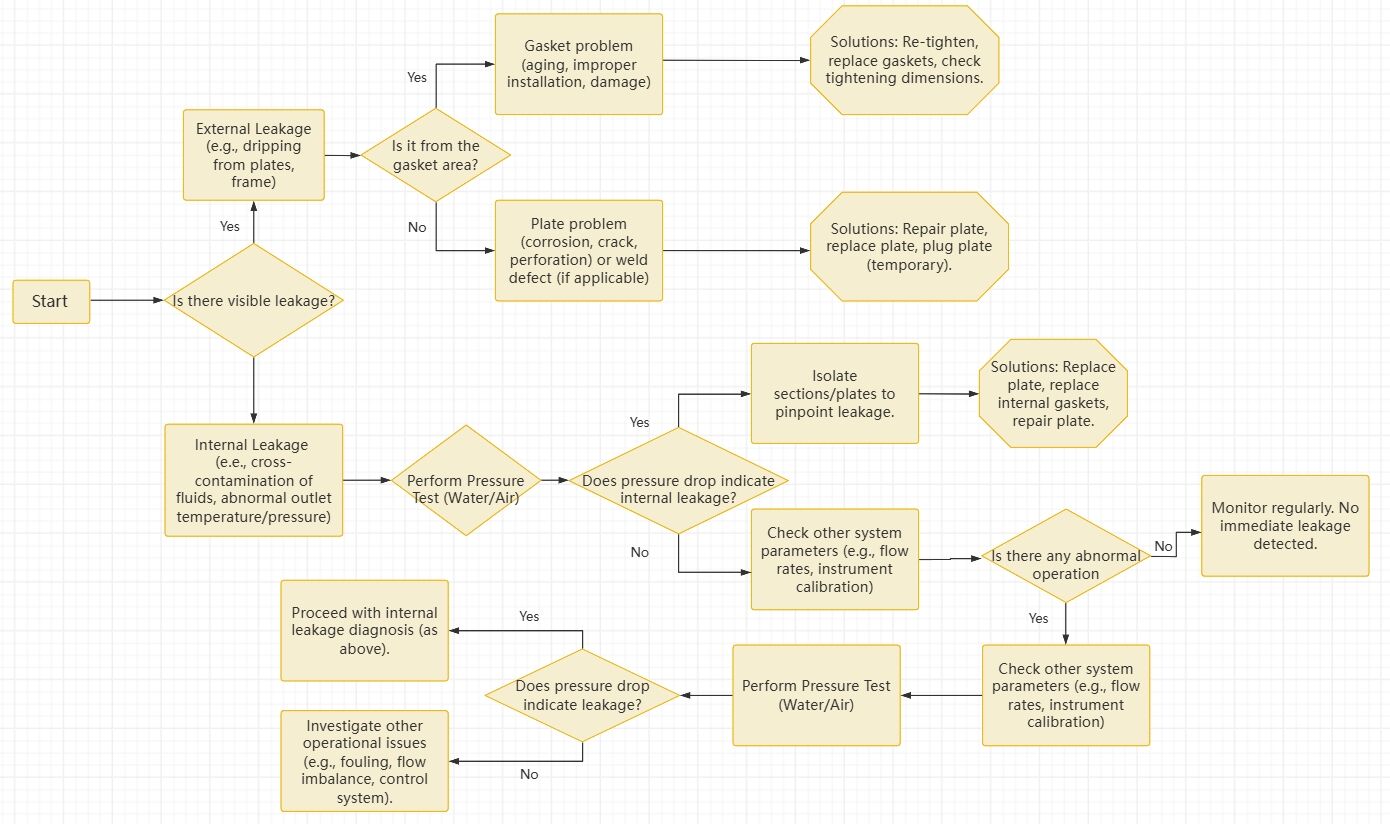

Flowchart of PHE Leakage Diagnosis

JINFAN is a factory specializing in the design and manufacture of plate heat exchangers with more than 15 years of industry experience. Our products include detachable, fully welded, semi-welded, brazed heat exchangers and accessories (plates, sealing gaskets). The factory is equipped with laser welding equipment, CNC equipment, and gasket molding production lines, supporting customization according to drawings and samples, and fast delivery.

Our engineering team can provide you with professional selection suggestions and technical support to help quickly locate problems and improve the stability of equipment operation.

If you encounter a problem that you cannot diagnose yourself during use, JINFAN provides the following service support:

📞 Online technical support/video diagnostic guidance

🧩 Original plate and gasket supply

🔧 Equipment modification and optimization suggestions

✅ Welcome to contact us for one-on-one technical support and quotation services!