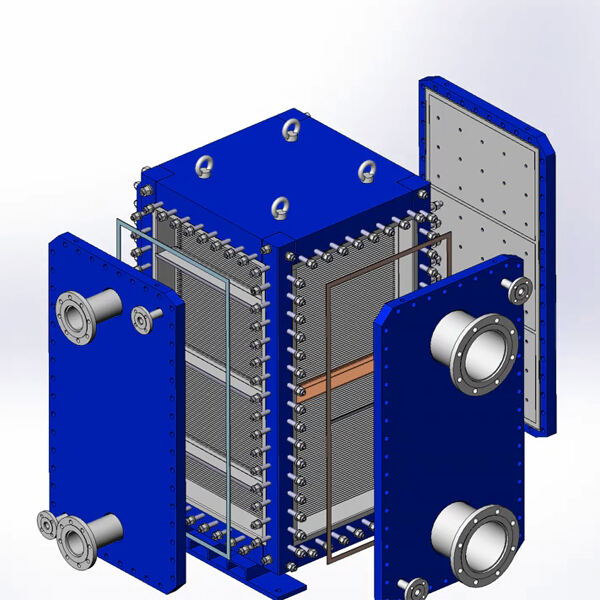

Our welded plate heat exchangers include fully-welded plate heat exchangers, plate and shell heat exchangers, bloc plate heat exchangers, etc. The welded plate heat exchanger means that the heat-transfer plates are welded together with no need for an external gasket. With a compact design, exceptional thermal transfer efficiency, and relatively low investment costs, WPHE boasts robustness and requires minimal cleaning and maintenance.

With welded plate heat exchangers, the risk of phe gasket failure is eliminated.

✅ High Efficiency: Corrugated plates create turbulence even at low flow, achieve close temperature matching.

✅ Gasket-Free Design: Fully automatic welding technology is used between the PHE Plates, eliminating the risk of heat exchanger gasket aging in traditional detachable plate heat exchangers.

✅ Resistant to Extreme Working Conditions: The welded heat exchanger is capable of withstanding working pressures (up to 4.0 MPa) and temperatures (up to 300°C or even higher) far exceeding those of traditional gasket plate heat exchangers.

✅ Low Maintenance Cost: No regular gasket maintenance is required, which greatly reduces the maintenance frequency and long-term operating costs of the equipment.