Plate heat exchangers, as highly efficient and energy-efficient heat exchangers, can experience performance degradation over time due to changes in operating conditions, material aging, and improper maintenance. If, even after cleaning, the equipment still experiences increased pressure drop and substandard heat transfer temperature differences, or if frequent leaks affect the operation of other equipment, it is recommended to promptly replace the entire plate heat exchanger or its core components to ensure system efficiency and safety.

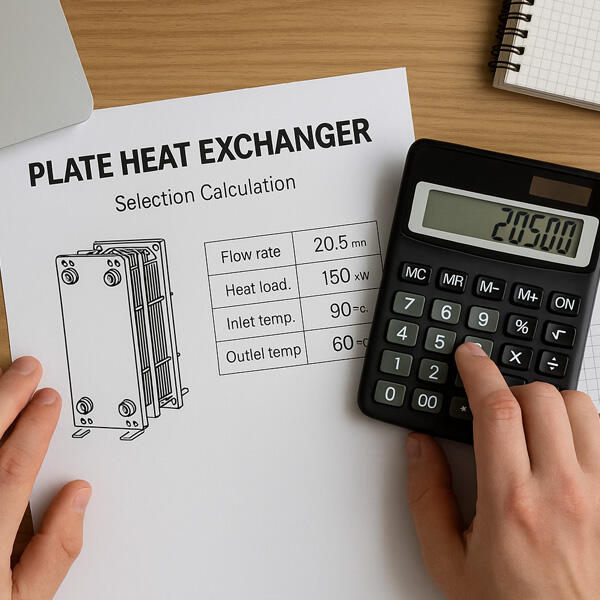

More PHE• Equipment Model and Parameters: Confirm the old heat exchanger's model, flow rate, heat transfer area, operating pressure, operating temperature, and other key parameters.

✅ Select an appropriate replacement.

• Operating Conditions: Understand the specific operating conditions of the equipment, including media type, fluid temperature, and pressure fluctuations.

✅ Special operating conditions may require the use of specialized materials that are corrosion-resistant, high-temperature, and high-pressure resistant.

• Installation Space and Piping: Measure the on-site installation space dimensions, including length, width, and height, as well as the connection methods, diameters, and routing of existing piping.

✅ Plan the dimensions and interface design of the new heat exchanger.

• Quotes are determined based on the heat exchange area, number of process channels, plate material (stainless steel, titanium, Hastelloy, etc.), and gasket material (NBR, EPDM, Viton, etc.).

• Custom designs are available, such as customized interface locations, brackets, and tripods.

• Plates (spare or additional)

• Gaskets (spare or consumable)

• Bolts, seals, guide rods, and other fasteners

• Support brackets, anchor bolts (if the original is no longer suitable)

• Pipes and valves (pipes, valves, flanges, gaskets, bolts, etc.)

• Water treatment equipment (additional water treatment equipment is recommended for poor water quality to extend the life of the heat exchanger)

• Other accessories (such as pressure gauges, thermometers, safety valves, etc.)

👉 Contact us, get model list of Plate type Heat Exchanger & PHE Spare part

• Logistics costs from the factory to the project site (depending on the distance, volume, weight, and transportation method)

• Additional costs such as wooden crating and rust protection

• Dismantling costs for the original plate heat exchanger equipment (including removal of the old heat exchanger, piping, flanges, etc., and proper waste disposal)

• Lifting of the new equipment (may require specialized equipment such as a forklift or crane)

• Installation and Connection (Reinstall the new plate heat exchanger and perform piping, flange, and bolt connections)

• Insulation (Is insulation required for the new heat exchanger?)

• Commissioning and Acceptance (After installation, hydraulic pressure testing, air tightness testing, system commissioning, and ensuring proper operation of the equipment are required.)

• Technical Staff Expenses (Site Survey, Design, Technical Support, etc.)

• Construction Staff Expenses (Hours of Installation, Commissioning, and Other Workforce)

• Project Management Expenses (Coordination, Supervision, and Administration of the Overall Project)

📦 Cost Breakdown - Plate Heat Exchanger Replacement.pdf