As an indispensable heat exchange equipment in modern industrial production, plate heat exchangers are widely used in HVAC, chemical industry, electricity, food and beverage, pharmaceutical and other fields. However, leakage problems in heat exchanger often occur during long-term operation, which not only leads to energy loss and product contamination, but also may cause production interruption, safety hazards and even equipment damage. Through scientific preventive maintenance and timely diagnosis and treatment, the risk of leakage can be minimized to ensure the long-term stable operation of the plate exchanger.

This article systematically analyzes the common causes of plate heat exchanger leakage, provides rapid diagnostic methods and effective solutions, and introduces how to avoid leakage accidents through management measures.

The leakage problems of plate heat exchangers are mostly caused by several key links: gasket aging, plate corrosion, improper installation, abnormal operating pressure or excessive cold and hot shock, etc. Especially in highly corrosive media or frequent start-stop working conditions, these problems are more likely to be exposed. Understanding the cause of the plate heat exchanger leakage is the first step in preventing and controlling the problem.

🔹 Common Reasons of Plate Heat Exchanger Leakage

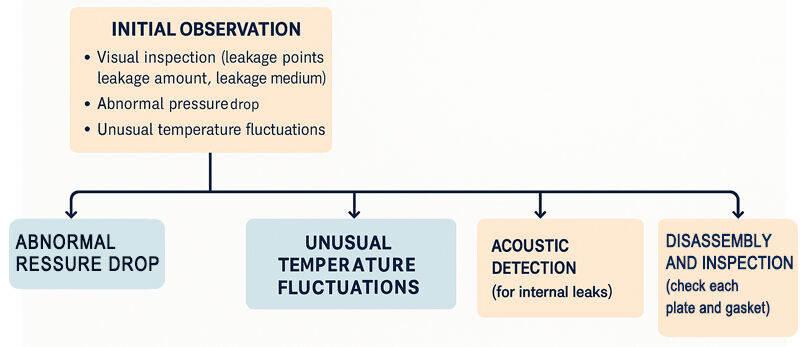

Accurately identifying the leakage point is crucial for a rapid repair. Common troubleshooting methods include: visually observing the traces of seepage, checking whether there is condensed water or liquid residue in the lower part of the plate exchanger, analyzing the system operation data, and using air pressure testing or dyeing testing for auxiliary diagnosis. In addition, many users ignore the signals of initial micro-leakage, such as a slight drop in system pressure or a decrease in heat exchange efficiency. Timely identification of these "early warnings" can prevent small problems from evolving into major failures.

🔹 Troubleshooting for Plate Heat Exchanger Leak

Flowchart for Diagnosing PHE Leak

For different types of leaks, corresponding solutions should be adopted. For example, replacing aging or damaged sealing phe gaskets, cleaning or replacing corroded phe plates, re-tightening heat exchanger equipment, adjusting operating parameters, etc. It is important to choose reliable quality accessories and professional technical support to ensure long-term, stable operation after maintenance.

JINFAN provides main brand plate type heat exchanger gaskets and plates replacement parts, and customized heat exchange solutions. The products have the advantages of corrosion resistance and high temperature resistance, ensuring service life and sealing performance.

🔹 Solutions of Plate Heat Exchanger Leakage Problems

Prevention is better than repair. Establishing a scientific equipment inspection plan, regular disassembly and cleaning of heat exchanger equipment, and replacing key wearing phe parts are effective ways to control leakage risks. At the same time, recording operating parameters and maintenance logs can help predict the health of equipment and take action before failures occur.

🔹 Preventive Measures for Plate Heat Exchanger Leakage

We can provide customers with customized maintenance plans and technical training to help factories establish a more complete equipment management system, extend the service life of heat exchangers, and improve production stability.

Leakage of plate heat exchangers is not unavoidable. The key lies in the understanding of the problem, the timeliness of response, and whether reliable accessories and technical support are selected. As a professional manufacturer focusing on heat exchanger system solutions, JINFAN has always been committed to providing customers with high-quality products and full-process services to reduce leakage risks from the source.