As core equipment for providing heat energy in industrial production and residential heating systems, boilers are widely used in hot water supply, steam generation, and energy conversion processes. The high-temperature hot water or steam generated by boilers must be transferred to heating systems or industrial processes through efficient heat exchangers.

Boiler plate heat exchangers are composed of a series of thin metal plates stacked to form alternating flow paths. The high-temperature primary medium on the boiler side and the low-temperature secondary medium on the user side to flow in opposite directions across the phe plates, achieving rapid and efficient indirect heat exchange. In actual operation, the performance and lifespan of plate heat exchangers are significantly affected by factors such as boiler operating water quality, maintenance level, and operating pressure. This article systematically summarizes the main issues with boiler plate heat exchangers based on actual engineering experience and troubleshooting reports.

When the boiler's primary water supply temperature is normal, the secondary outlet water temperature cannot reach the set value, resulting in insufficient heating or insufficient domestic hot water temperature. Consider whether equipment scaling is blocking the flow paths:

1.1 Calcium carbonate/calcium sulfate scale, formed by the heating of calcium and magnesium ions in boiler water, easily deposits on the phe plate surfaces. Scale has an extremely low thermal conductivity (only 1/50 that of stainless steel), forming a significant thermal resistance layer that severely hinders heat conduction.

1.2 Welding slag, rust, biological slime, or fibrous impurities in the system piping can enter the boiler plate heat exchanger with the water flow, blocking the mere millimeters wide flow channels between the plates, reducing the effective heat transfer area and dramatically reducing flow rate.

heat exchanger plate corrosion

high quality phe gasket replacement

Leakage is one of the most common boiler plate heat exchanger failures and can be categorized as external or internal. External leakage occurs when the medium seeps through the seal between the plate pack and the external environment, causing loss of medium and potentially contaminating the surrounding environment. Internal leakage occurs when the two media mix within the heat exchanger, directly impacting system functionality.

2.1 External Leakage

Long-term high-temperature operation can cause rubber phe gaskets to age, lose elasticity, harden, and crack, or chemical corrosion can occur in the water. Stress caused by thermal expansion and contraction during equipment startup and shutdown can cause gasket slippage. Improper operation can also cause plate deformation or cracking.

2.2 Internal Leakage

Chloride ion stress corrosion (especially in stainless steel plates), pitting corrosion, or abrasion caused by solid particles in the water flow can cause localized thinning of the heat exchanger plates, leading to penetration. Damage or misalignment of the heat exchanger gasket around the corner holes can result in direct communication between the two media at the ports.

When the pressure differential (ΔP) between the inlet and outlet of the equipment is significantly higher than the design value, resulting in excessive system circulation resistance, reduced flow rate, and increased pump energy consumption, this typically indicates abnormal internal resistance within the heat exchanger. Similar to the causes of reduced efficiency, dirt and scale in the flow channel reduce the flow cross-sectional area, increasing fluid resistance exponentially. Alternatively, overly narrow flow channels or excessively high fluid velocities can also lead to increased pressure drop. The increase in pressure drop directly causes the system circulation pump to consume more electricity to maintain flow, increasing operating costs. It also affects the hydraulic balance of the entire heating system, which may lead to insufficient heating for end users.

boiler plate heat exchanger pressure test

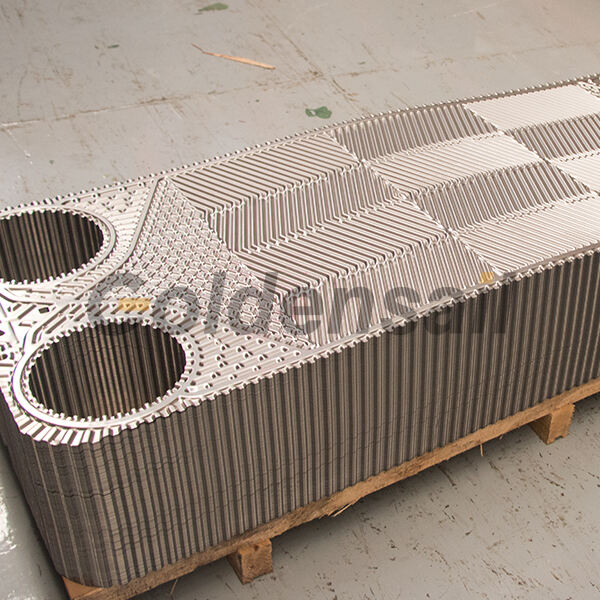

high quality phe plate

A hammer-like sound is emitted from the equipment‘s internal, accompanied by intense vibration. In severe cases, this can instantly cause phe plate deformation, gasket tearing, even rupture, or the pipe flanges, welds, etc. of the boiler plate heat exchanger may be cracked. Causing hidden dangers to system operation security.

4.1 Liquid Water Hammer

This is the most typical "valve-closing water hammer." When liquid in a flow channel is flowing at a certain velocity, the outlet valve is suddenly and rapidly closed. The fluid's kinetic energy is instantly converted into enormous pressure energy. This massive pressure surge violently impacts the heat exchanger plates in the form of a pressure wave, far exceeding their designed pressure capacity.

4.2 Steam Condensation Water Hammer

Steam releases heat in the boiler plate heat exchanger and condenses into water. If the steam trap is improperly selected, damaged, or clogged, the condensate cannot be discharged promptly. High-speed steam enters the heat exchanger, pushing the condensate forward through the pipes. When the high-speed condensate encounters an obstacle, its kinetic energy is instantly converted into pressure due to the incompressibility of water, resulting in an extremely violent impact.

Boiler plate heat exchangers do offer certain advantages in industrial applications, but they also present challenges such as severe scaling, difficult maintenance, insufficient energy efficiency, leakage risks, and poor adaptability. To address the limitations of boiler plate heat exchangers, modern industry is gradually introducing new heat exchange equipment: fully welded plate heat exchangers, semi-welded plate heat exchangers, and plate and shell heat exchangers. Companies need to balance initial investment and maintenance costs to select the appropriate heat exchanger to improve overall production safety and reliability.