Titanium plate heat exchanger is a heat exchange device composed of multiple titanium metal plates, which realizes heat exchange between cold and hot fluids through the flow channels between plates. Titanium material exhibits excellent corrosion resistance and high thermal conductivity, making it particularly suitable for handling corrosive media or high-temperature environments. The titanium plate heat exchanger is an efficient and energy-saving heat exchange device, widely used in the chemical, pharmaceutical, food processing, and other industries.

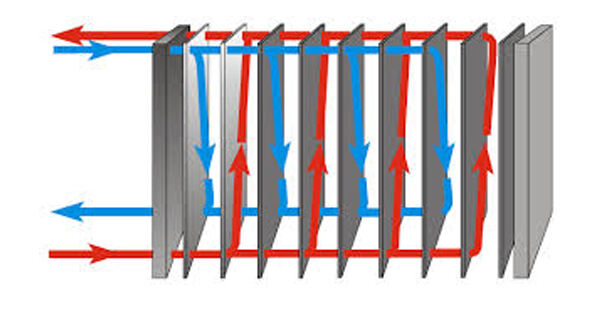

In the titanium plate heat exchanger, the cold fluid and the hot fluid enter different flow channels of the heat exchanger respectively, and the titanium plate completely isolates the two fluids to avoid mixing. The heat of the hot fluid is transferred to the cold fluid through the titanium plate, and the high thermal conductivity of titanium ensures efficient heat exchange. The surface of the titanium plate is usually designed to be corrugated to increase the turbulence of the fluid and improve the heat exchange efficiency. The fluid circulates in the flow channel between the plates and flows out from the outlet after completing the heat exchange. The thickness of the titanium plate is usually 0.4-0.6mm, which not only ensures efficient heat exchange but also reduces material costs. The corrugated design can also reduce scaling and improve the stability of equipment operation.

Working principle diagram

Want to learn how to choose the right titanium plate heat exchanger for your project? Contact us, get a professional selection guide!

Efficient heat exchange: The corrugated plate design increases the heat exchange area, and the thermal efficiency is 20%-30% higher than that of traditional heat exchangers.

✅ Corrosion resistance: Titanium material can resist corrosive media such as acids, alkalis, and salts, extending the service life of the equipment.

✅ Compact structure: Small size, light weight, saving installation space, suitable for a variety of industrial scenarios.

✅ Easy maintenance: Modular design, easy to disassemble and clean, reducing maintenance costs.

Titanium plate heat exchangers are widely used in the following industries:

✅ Chemical Industry: Handles corrosive media like sulfuric or hydrochloric acid under high temperatures and pressures.

✅ Marine Engineering: Resists seawater corrosion, ideal for ship cooling systems and desalination plants.

✅ Food Processing: Meets hygiene standards for pasteurization and cooling of milk, juice, and other fluids.

✅ Pharmaceuticals: Ensures precise temperature control for high-purity fluids, compliant with GMP standards.

✅ Renewable Energy: Supports cooling fluid circulation in solar and wind energy systems, enhancing efficiency.

| Property | Titanium Plates | Stainless Steel Plates (304/316L) |

|---|---|---|

| Corrosion Resistance | Excellent, resistant to strong acids (e.g., sulfuric acid, hydrochloric acid), alkalis, and seawater. Ideal for harsh environments. | Good, with 316L offering moderate resistance to corrosion, but less effective against chlorides and strong acids. |

| Thermal Conductivity | 15-20 W/(m·K), enabling high heat transfer efficiency. | 14-17 W/(m·K), slightly lower than titanium but comparable. |

| Weight | Low density (4.51 g/cm³), lightweight, ideal for mobile or space-constrained applications. | Higher density (~8 g/cm³), heavier, less suitable for weight-sensitive applications. |

| Service Life | Up to 10-15 years in corrosive environments due to superior durability. | 5-10 years in general conditions, shorter in corrosive settings. |

| Cost | Higher initial cost but lower maintenance and longer lifespan, offering better long-term value. | Lower initial cost but higher maintenance and replacement frequency. |

| Applications | Chemical processing, marine engineering, seawater desalination, pharmaceuticals. | Food processing, HVAC, general industrial cooling. |

We provide high-quality titanium plate heat exchangers and accessories, and our products have been strictly tested and meet international standards. Whether you need a customized solution or a standard model, we can meet your needs. Contact our professional team now for free consultation and customized solutions, get the Best Price!

✅ 30 years of industry experience, providing professional technical support

✅ Support customized design to meet specific working conditions

✅ Perfect after-sales service, 7x24 hours to respond to customer needs

Get in touch

an extensive inventory of spare parts

Q: What is the price of titanium plate heat exchanger?

A: The price varies depending on the model, number of plates and customization requirements. Welcome to contact us for a detailed quotation!

Q: How to choose the right heat exchanger model?

A: Selection is based on parameters such as flow rate, temperature difference, medium type, etc. Check out our selection guide or contact the technical team for support.

Q: Does the titanium plate heat exchanger require regular maintenance?

A: Yes, it is recommended to clean it every 6-12 months to maintain efficient operation. Our modular design makes cleaning easier and faster.