Looking for a Gasket Plate Heat Exchanger for corrosion-resistant? Then JINFAN is just right.

We are a first class plate heat exchanger manufacturer & supplier. With many years of R&D experience, JINFAN plate heat exchanger combination has resulted in the most optimal heat transfer solution for highly corrosive fluids.

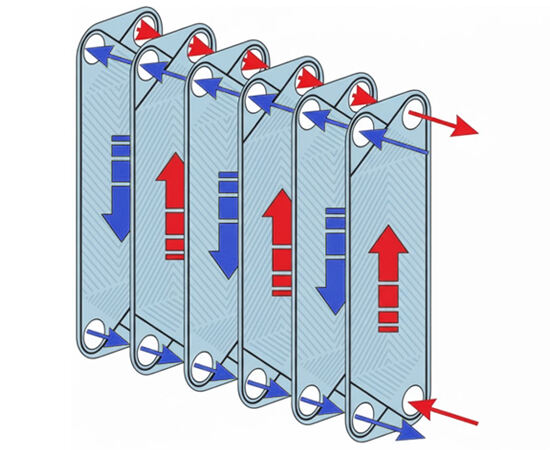

A Gasket Plate Heat Exchanger is a highly efficient heat exchange equipment. Suppose the PHE core component, the heat exchanger plate, is made of a metal material with excellent corrosion resistance. So, they can handle a wide range of heat exchange processes involving corrosive media, such as acids, alkalis, saline solutions, and seawater. Like other Gasket Plate Heat Exchangers, hot and cold fluids alternate between adjacent corrugated plates, achieving efficient heat transfer through the thin plates. Because the material selection and structural design prioritize corrosion resistance, they are protected from corrosion in acidic, alkaline, or chloride-containing environments.

High-temperature and low-temperature fluids enter the heat exchanger through separate inlets. They flow through the channels formed between adjacent heat transfer plates, completely separated by the corrosion-resistant plates to prevent mixing. The two fluids typically flow in countercurrent to achieve higher heat transfer efficiency. The special corrugations in the plates generate intense turbulence, which not only effectively promotes heat transfer between the fluid and the plates, significantly improving the heat transfer coefficient, but also helps reduce fouling. Heat is transferred from the high-temperature fluid to the low-temperature fluid through the extremely thin, corrosion-resistant plates, completing the heat exchange. The two fluids that have completed the heat exchange flow out of the heat exchanger through their respective outlets.

✅ Dependable performance coupled with high corrosion resistance.

✅ Energy conservation through exceptional thermal efficiency.

✅ Efficient heat recovery is achieved with a minimal temperature differential.

✅ Extended service intervals and decreased fouling.

✅ Compact units that save space and are effortless to install and maintain.

JINFAN gasket plate heat exchangers are efficient heat exchange equipment with a compact design. The GPHE, featuring top-quality spare parts, meets the requirements for a corrosion-resistant, easily serviceable, and thermally efficient heat exchanger. Our gasket plate heat exchanger can be used as heaters, coolers, interchangers, condensers and evaporators for corrosive media. Contact us to get corrosion-resistant plate heat exchanger PDF.

✅ Years of experience in processing and welding corrosion-resistant metal materials

✅ Customized heat exchange solutions based on the customer's media, temperature, and pressure.

✅ Fully inspected to ensure corrosion resistance and structural strength.

✅ Extensive experience in desalination, chemical, and energy projects.

✅ Providing fast quotes and technical support.

"We are highly satisfied with the new titanium plate heat exchanger installed. The titanium unit has demonstrated exceptional corrosion resistance, maintaining its structural integrity perfectly after more than a year in service. This reliability is critical to our continuous operation."

"After replacing JINFAN heat exchanger, we've seen a dramatic improvement. It makes disassembly for cleaning and plate inspection during the off-heating season incredibly quick and straightforward, significantly reducing our maintenance time and labor costs."

| Plate Material | Suitable Media | ||||||

|---|---|---|---|---|---|---|---|

| Stainless Steel (304/316) | Pure Water, River Water, Edible Oil, Mineral Oil | ||||||

| Ti, Ti-Pd | Seawater, Brine, Salt Substance | ||||||

| 20Cr,18Ni,6Mo (254MO) | Dilute Sulfuric Acid, Dilute Salt Substance Aqueous Solution, Inorganic Aqueous Solution | ||||||

| Ni | High Temperature, High Density Caustic Soda | ||||||

| Hastelloy (C276, D205, B2G) | Concentrated Sulfuric Acid, Hydrochloric Acid, Phosphoric Acid | ||||||

| Gasket Material | Operating Temperature | Suitable Media | |||||

|---|---|---|---|---|---|---|---|

| NBR | -20℃ to +110℃ | Water, sea water, mineral oil, salt, brine | |||||

| EPDM | -50℃ to +150℃ | Hot water steam, acid, alkali | |||||

| HNBR | -15℃ to +160℃ | High temperature, mineral oil, water | |||||

| VITONA/VITONG/FKM | -35℃-+180℃ | High temperature, high resistance, strong oxidant, oil, acid, alkali, etc | |||||