Looking for a titanium plate heat exchanger? Then JINFAN is just right.

We are a first-class titanium plate heat exchanger manufacturer & supplier. JINFAN's range of heat exchangers caters to a wide variety of applications, including food, dairy, beverages, biotech, pharmaceuticals, etc.

Titanium is a very special metal with the characteristics of high strength, low density, non-magnetic conductivity and super corrosion resistance. It is lightweight while ensuring a strong structure. It is particularly suitable for heat exchange in media such as chloride ions, seawater, acidic and alkaline solutions.

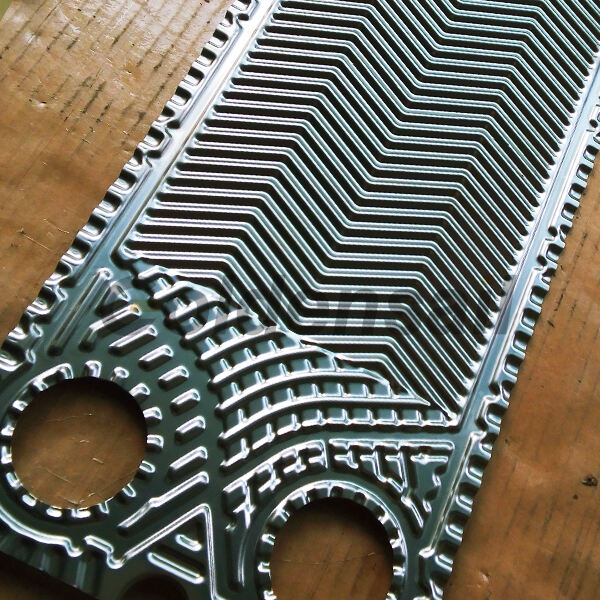

Plate heat exchangers are currently the most efficient heat exchange equipment, with the characteristics of compact structure and high heat transfer efficiency. Gasket-type plate heat exchangers have been widely used in various industries, relying on their advantages such as easy disassembly, cleaning and maintenance, and easy capacity expansion. The Titanium Plate Heat Exchanger is a highly efficient heat exchange device that utilizes titanium metal as its heat transfer element. It primarily consists of corrugated titanium plates, sealing heat exchanger gasket, and frame. Narrow flow channels are formed between the plates, allowing two fluids of different temperatures to flow through adjacent channels, exchanging heat through the titanium plates to achieve heating or cooling.

titanium plate details

The titanium plate heat exchanger's working principle is similar to that of an ordinary plate heat exchanger. It consists of a series of corrugated titanium plates placed alternately to form flow channels. The titanium plate heat exchanger is mainly made of a frame and a titanium plate. The heat transfer plate is pressed into a concave and convex wave pattern and sealed with a synthetic rubber sealing gasket. The required number of the above heat transfer plates is suspended on the guide rod and overlapped between the fixed frame and the movable frame, and fixed with screws. A plate separates the high-temperature fluid and the low-temperature fluid and flow alternately in the flow path formed between the plates to perform heat exchange processing.

Due to the corrugated design on the plates, the fluid will form a high degree of turbulence in the channel, which greatly increases the contact area between the fluid and the plates and the heat exchange efficiency. The hot fluid and the cold fluid enter these alternating channels. The two fluids usually flow in a countercurrent manner, that is, the inlet of the hot fluid faces the outlet of the cold fluid. This method can maximize the use of temperature differences and achieve higher heat exchange efficiency. Heat is transferred to the cold fluid through the titanium plate to complete the heat exchange. The sealing gasket between the plates ensures that the two fluids do not mix while preventing external leakage.

✅ Titanium metal has good corrosion resistance and is particularly suitable for alkaline fluids. Heat exchangers using titanium as the plate material are widely used in seawater cooling and other corrosive media heat transfer.

✅ Relying on the design of the gasketed plate, the heat exchange area can be maximized, making heating or cooling more efficient. At the same time, the compact design can minimize the floor space.

✅ The detachable design is easier to maintain and clean, ensuring the best performance of the PHE during its service life.

"After nearly three years of operation, when we opened it for inspection, the plate surface remained as bright as new, with virtually no signs of corrosion. We no longer have to worry about engine failures caused by cooler leaks."

"Titanium demonstrates excellent resistance to the chloride ions and acidic environment in our process. Regular testing of the media composition over the past two years has revealed no metal ion contamination, completely eliminating the problem of product contamination caused by equipment corrosion."

| Gasket Material | Operating Temperature | Suitable Media | |||||

|---|---|---|---|---|---|---|---|

| NBR | -20℃ to +110℃ | Water, sea water, mineral oil, salt, brine | |||||

| EPDM | -50℃ to +150℃ | Hot water steam, acid, alkali | |||||

| HNBR | -15℃ to +160℃ | High temperature, mineral oil, water | |||||

| VITONA/VITONG/FKM | -35℃-+180℃ | High temperature, high resistance, strong oxidant, oil, acid, alkali, etc | |||||