Looking for gasketed type plate heat exchanger? Then JINFAN is just right.

We are a first class plate heat exchanger manufacturer & supplier. Our wide range of Gasketed plate heat exchanger ensures an efficient solution for your application. Brands include APV, FUNKE, TRANTER, GEA, SONDEX, Sigma, HISAKA, VICARB, Thermowave, Botai, etc.

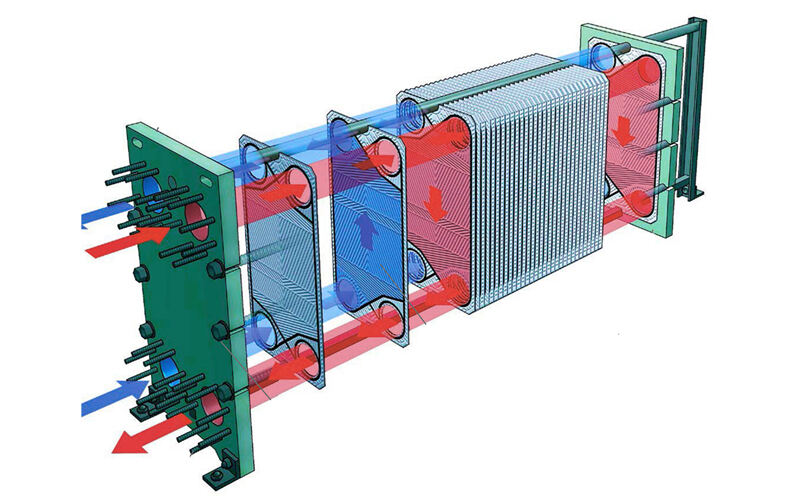

A Gasket Plate Heat Exchanger is a highly efficient and compact heat exchange device. The heat transfers between two fluids through a series of corrugated metal plates. The number of PHE Plates can be increased or decreased to meet the heat load requirements. Loosening the compression bolts, the removable plate can be removed, allowing for complete disassembly for thorough cleaning and maintenance.

Frame: Contains the fixed and movable plates, upper and lower guide rods, and compression bolts.

Plate Pack: A large number of metal plates (usually made of stainless steel, titanium, etc.) with herringbone corrugations are aligned and stacked on the guide rods. Each plate has access holes at its four corners.

Gasket: A sealing gasket is installed between each pair of plates. Gaskets not only seal to prevent fluid leakage but also cleverly guide fluid flow, allowing it to alternate within its respective flow channels.

gasket plate heat exchanger working principle diagram

In a gasketed plate heat exchanger, two different temperature fluids flow alternately through different flow channels separated by plates, heat being transferred from the high-temperature fluid to the low-temperature fluid through the thin plates. The unique corrugated design of the heat exchanger plates not only increases the rigidity of the plates but also guides the fluid flow, creating turbulence and thus improving heat transfer efficiency. Each plate has openings at the four corners for the fluid to enter and exit. The hot fluid flows into a corner hole on the fixed plate and is guided by a gasket into the odd-numbered flow channel. Simultaneously, the cold fluid flows in through the other corner hole and is guided into all even-numbered flow channels. In this way, the two fluids flow in opposite directions in adjacent flow channels. Heat is transferred from the higher-temperature fluid through the metal phe plate to the lower-temperature fluid, completing the heat exchange.

| FM3 | FM6B | FM6M | FM6MX | FM10B | FM10M | FM15E | FM15B |

| FM15M | FMX25M | FMX25B | FM30 | FMA30S | FMA30W | FMA30M | FM6MW |

| FM10BW | FMK15BW | FAM10 | FA10B | FA15B | FAM20B | FA20B | FAM20 |

| FAK20 | FAX30B | FAX30BW | FClip6 | FClip8 | FClip10 | FClip15 | JFTL6B |

| JFTS6M | JFTL10B | JFTL10P | JFTL15B | JFT20M | JFT20MW | JFT20B | JFT20P |

| JFTS20M | JFT20S | FP16 | FP26 | FP32 | FP36 |

| FP04 | FP08 | FP05 | FP09 | FP10 | FP16 | FP22 | FP205 |

| FP31 | FP40 | FP41 | FP42 | FP50 | FP60 | FP62 | FP70 |

| FP71 | FP80 | FP82 | FP100 | FP112 | FP130 | FP405 |

| GC008 | GL13 | GX12 | GX18 | GC16 | GC26 | GX26 | GX42 |

| GX51 | GC51 | GC60 | GX60 | GX100 | GX140 | GX64 | GX91 |

| GX118 | GX85 | GX145 | GX205 | GL230 | GL330 |

| VT04 | VT10 | VT20 | VT205 | VT20P | VT40 | VT40(M) | VT405P |

| AT405 | VT405 | VT80 | VT80(M) | VT805 | VT2508 | NT50T | NT50M |

| NT50X | NT100T | NT100M | NT100X | NT150L | NT150S | NT250S | NT250M |

| NT250L | NT350S | NT350M | NH350S | NH350M | FA184 | N40 |

| S4A | S8A | S7A | S14A | S20A | S16B | S9A | S19A |

| S31A | S17 | S21 | S21A | S22 | S37 | S41 | S41A |

| S42 | S63 | S43H | S43A | S43 | S65 | S100 | S47 |

| S64 | S81 | S121 | S188 | S62 | S86 | S110 | S113G |

| SF123 | SF160 |

| Sigma09 | Sigma13 | Sigma26 | Sigma36 | Sigma37 | Sigma25 | Sigma35 | Sigma55 |

| Sigma35 | Sigma55 | Sigma85 | Sigma56 | Sigma76 | Sigma96 | Sigma66 | Sigma106 |

| Sigma136 | Sigma156 | Sigma90 | G33 |

| T4 | H17 | N25 | N35 | N50 | Q030E | Q055E | Q080E |

| Q030D | Q055D | Q080D | A055 | A085 | A145 | J060 | J092 |

| J107 | J154 | J185 | M060 | M092 | M107 | SR2 | SR3 |

| R5 | SR6GL | SR6AG | R8GI | SR9 | R10 | R14 | SR14AP |

| B063 | B110 | B134 | B158 | B205 | P105 | P190 | TR9AL |

| TR9AV | TR9GN | TR9GL | K34 | K55 | K71 |

| EX3 | CX70 | UX10A | UX20 | UX40 | UX80 | UX90 | RX50A |

| RX70 | LX10A | LX30 |

| V2 | V4 | V8 | V13 | V20 | V28 | V45 | V60 |

| V100 | V110 | V130 | V170 | V280 |

| TL90P | TL150P | TL90S | TL150S | TL200P | TL400P | TL200S | TL400S |

| TL250P | TL500P | TL250S | TL500S | TL250SSW | TL500SSW | TL650P | LT850P |

| TL650S | TL850S |

| HT062 | HT102 | M6MA | M6-D | M6MC | TS6MD | TS6ML | SF123D |

| M10BWC | M10MC | M10MD | M10BC | M10BC | M10BD | M15MC | M15BC |

| MX25MA | MX25MB | M30MC | AK20C | JF021 | BR003 | BR005 | BR007 |

| BB05 | BB09 | BB1.2 | BR1.3 | BR06 | BR08 | BB03 | BB045 |

| BB06X | BB04 | BB06 | BB08 | BR2.5 | BR2.0 |

** Explore More Gasketed Plate Heat Exchanger Model

| Plate Material | Suitable Media | ||||||

|---|---|---|---|---|---|---|---|

| Stainless Steel (304/316) | Pure Water, River Water, Edible Oil, Mineral Oil | ||||||

| Ti, Ti-Pd | Seawater, Brine, Salt Substance | ||||||

| 20Cr,18Ni,6Mo (254MO) | Dilute Sulfuric Acid, Dilute Salt Substance Aqueous Solution, Inorganic Aqueous Solution | ||||||

| Ni | High Temperature, High Density Caustic Soda | ||||||

| Hastelloy (C276, D205, B2G) | Concentrated Sulfuric Acid, Hydrochloric Acid, Phosphoric Acid | ||||||

| Gasket Material | Operating Temperature | Suitable Media | |||||

|---|---|---|---|---|---|---|---|

| NBR | -20℃ to +110℃ | Water, sea water, mineral oil, salt, brine | |||||

| EPDM | -50℃ to +150℃ | Hot water steam, acid, alkali | |||||

| HNBR | -15℃ to +160℃ | High temperature, mineral oil, water | |||||

| VITONA/VITONG/FKM | -35℃-+180℃ | High temperature, high resistance, strong oxidant, oil, acid, alkali, etc | |||||

When your plate heat exchanger is no longer fit for duty, maybe it's time to replace your PHE parts. Choosing high-quality plate type heat exchanger spare parts can improve performance and cut costs.

"Due to the declining efficiency of our old heat exchange equipment, we replaced it with a new detachable plate heat exchanger. This significantly improved steam utilization, accelerated cooling, and reduced energy consumption by approximately 15%."

"Before replacing it with the new removable plate heat exchanger, our production line was frequently impacted by sealing issues and insufficient heat transfer. Now, the discharge temperature is more stable, process control is more precise, and maintenance workload has been significantly reduced."

Semi-welded GPHE

The sides of each two corrugated plates in the Semi-welded Plate Heat Exchanger are welded into a plate bundle to form a flow channel for non-corrosive media. The two plate bundles are then welded together to form a flow channel for corrosive media on the sides between each two plate bundles. These plate groups are assembled between the fixed plate and the clamping plate, and tightened by tightening the bolts.

Wide-gap GPHE

Wide Gap Plate Heat Exchangers are perfect for handling rough and viscous blocky fluids. The wide gap between the plates allows fiber particles to easily pass through the heat exchanger. Reduce the possibility of clogging and maximize the normal use time of the process. Compared with shell and tube heat exchanger, wide-gap type offer a more compact footprint and higher thermal efficiency.

Stainless Steel GPHE

Presses high-quality stainless steel plates (such as 316L) into heat exchanger plates with a certain corrugation shape, and with the stainless steel frame plate and clamping bolts, it forms the whole machine. The fluid flows through the channel formed between the two plates, and the hot and cold fluids flow through the plate for heat exchange. Jinfan Stainless Steel Gasket Heat Exchanger uses stainless steel materials that meet FDA requirements.

Titanium GPHE

Titanium Plate Heat Exchangers with seawater as the fluid medium are widely used in the heating, cooling, condensation and evaporation processes of chemical plants, power generation facilities and large ships. Titanium material has excellent seawater corrosion resistance and better heat transfer performance. Titanium plate heat exchangers are suitable for extreme temperature conditions and have a longer service life.

Need Gasket Plate Heat Exchanger, GPHE Spare Parts price list? Seeking a customized solution for Energy Savings?

Our expert team is ready to assist you! Contact us or email [email protected] today to discuss your needs,

and let us help you maximize efficiency for heat exchange. Our goal is to ensure your complete satisfaction.