Every sewage treatment project is unique. JINFAN customizes the right heat exchanger solution to efficiently utilize energy, reduce operating costs.

At the sewage works, People pass the wastewater through several cleaning and filtering processes so that we can return it safely into rivers. According to the type of sewage, sewage treatment plants are divided into sewage treatment plants, industrial wastewater treatment plants, agricultural wastewater treatment plants, and leachate treatment plants.

1. Physical treatment: using physical action to separate insoluble substances in sewage without changing the chemical properties during the treatment process. Commonly used methods include gravity separation, centrifugal separation, reverse osmosis, flotation, etc.

✅ Physical treatment structures are simpler and more economical, and are used in villages and towns with large water capacity, strong self-purification ability, and low sewage treatment requirements.

2. Chemical treatment: a method of using chemical reactions to treat or recover dissolved substances or colloidal substances in sewage, mostly used for industrial wastewater. Commonly used methods include coagulation, neutralization, oxidation-reduction, ion exchange, etc.

✅ Chemical treatment has a good treatment effect and high cost, and is often used as effluent after biochemical treatment for further treatment to improve effluent quality.

3. Biological treatment: Utilize the metabolic function of microorganisms to decompose and oxidize organic matter in the sewage in the dissolved or colloidal state into stable inorganic substances, so that the sewage can be purified. Commonly used methods are the activated sludge method and the biofilm method.

✅ Biological method has a higher degree of treatment than physical method.

In recent years, sewage treatment technology has been developing towards high efficiency and energy conservation. Temperature is an important factor affecting efficiency and energy consumption. Especially in the biochemical treatment and sludge anaerobic digestion stages, the appropriate temperature can greatly improve the activity of microorganisms and accelerate the degradation of pollutants, thereby improving efficiency, shortening the treatment cycle, and reducing energy consumption.

In winter or cold areas, low-temperature sewage directly entering the treatment system is likely to cause a decrease in treatment efficiency. Therefore, introducing efficient heat exchange equipment to preheat sewage in the sewage treatment system has become an important means to optimize efficiency and reduce energy consumption.

1. Influent preheating

Sewage water temperature is affected by seasonal changes. Too low a temperature will directly lead to reduced biological activity and reaction efficiency, which may cause the treatment efficiency to drop by more than 20%. Using plate heat exchanger, the sewage is heat exchanged with an external heat source to increase the sewage temperature to 25℃~35℃, ensure the metabolic reaction rate of microorganisms, and improve sludge activity. PHE has a higher heat exchange efficiency than other heat exchangers, it can quickly respond to changes in influent temperature to ensure stable operation of the system.

2. Sludge heating

Sludge is rich in organic matter and can produce biogas through anaerobic digestion. Anaerobic bacteria are susceptible to temperature. Temperature fluctuations will directly affect gas production and digestion efficiency. The most suitable digestion temperature is 35℃/55℃. Using plate to plate heat exchanger, heat is transferred to the concentrated sludge entering the digester to keep the temperature of the anaerobic digestion system constant, avoid microbial inactivation, and improve the decomposition rate of organic matter.

3. Waste heat recovery

The treated effluent/slurry is still at a high temperature. Direct discharge will cause heat waves. Reasonable waste heat recovery can greatly improve the energy efficiency of the sewage treatment plant. Using plate and frame heat exchanger to recover heat and transfer it to the low-temperature sewage newly entering the system will effectively reduce energy consumption.

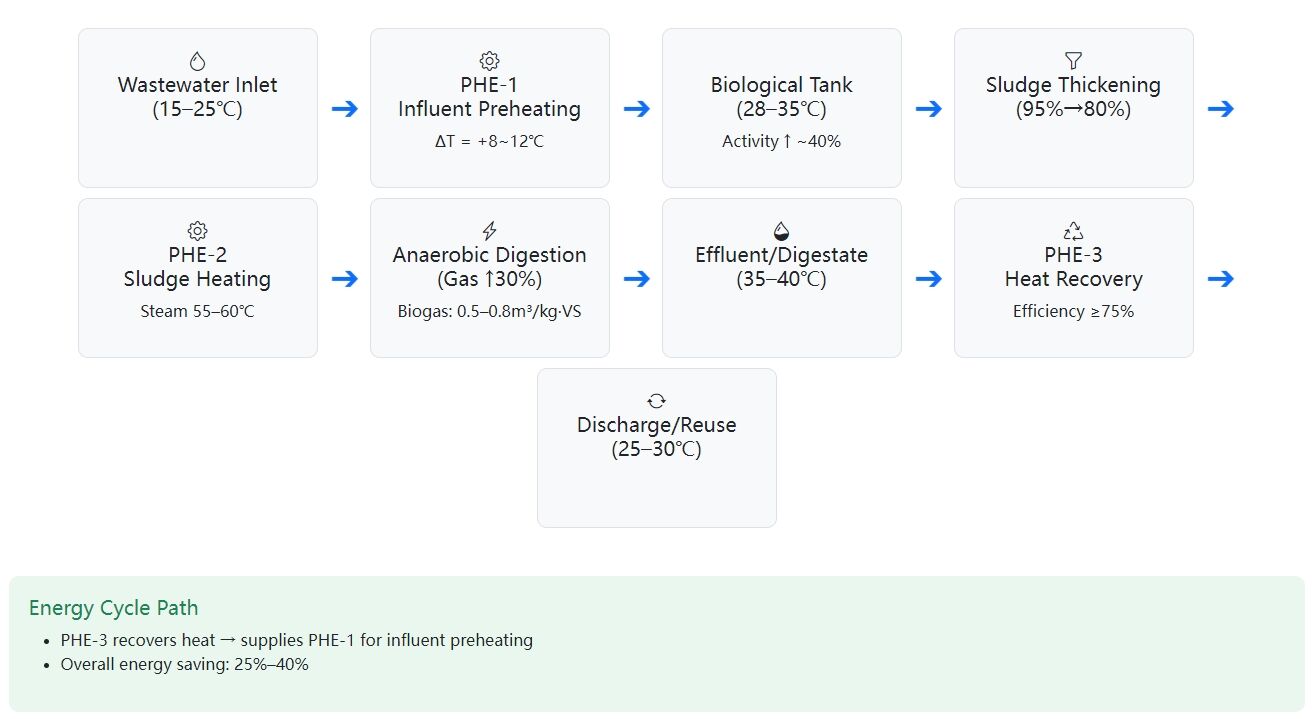

Schematic diagram of phe in the sewage purification process

✅ Plate Heat Exchanger efficiency is much higher than traditional shell and tube heat exchangers, reaching more than 90%

✅ Compact design, small footprint, easy to modify or add to the existing sewage treatment system

✅ Detachable design, easy to clean and maintain, ensuring long-term efficient operation

✅ By increasing or decreasing the number of plates, it is easy to adapt to different treatment scales

| Type | Suitable Wastewater Stage | Advantages | Disadvantages |

|---|---|---|---|

| Detachable Type | Influent Preheating, Biological Tank Heating | Easy to clean, flexible expansion, low cost | Gasket needs regular replacement, limited high-temp resistance |

| Brazed Type | Clean Water, Heating Systems | Compact, efficient, maintenance-free | Not resistant to fouling, not repairable after clogging |

| Fully Welded Type | Sludge Heating, Corrosive Liquid Treatment | High temp and pressure resistance, long lifespan | High cost, difficult to clean |

| Semi-welded Type | Corrosive Wastewater, Biogas Cooling | Good corrosion resistance, easier maintenance | Relatively high cost, more complex system |

🎯 In the sewage purification system, the selection of PHE Heat Exchangers needs to be comprehensively considered based on factors such as sewage quality, system pressure, operation and maintenance. Select the appropriate plate heat exchanger type to maximize system efficiency and reliability while effectively reducing operation and maintenance costs.

✅ Limited initial investment, clean water or mild sewage treatment → Detachable plate heat exchangers can be preferred

✅ High requirements for system stability and corrosion resistance → Fully welded or semi-welded plate heat exchangers are recommended

✅ Clean media, high temperature and high pressure conditions → Brazed type can be used as auxiliary heating equipment

| Material Type | Features | Suitable Wastewater Application |

|---|---|---|

| 304 Stainless Steel (SS304) | General corrosion resistance, good temperature tolerance | Neutral or mildly acidic/alkaline water, low-corrosion primary wastewater |

| 316 Stainless Steel (SS316) | Contains molybdenum, chloride-resistant, high-temperature resistant | Salty water, wastewater with high chloride content, municipal sewage, food industry wastewater |

| Titanium | Excellent corrosion resistance, especially against seawater and acids | High salinity wastewater, seawater treatment, strong acid wastewater |

| Hastelloy C-276 | Superior resistance to strong oxidizing and reducing agents | Highly corrosive wastewater, strong acid/alkali and high chloride industrial wastewater |

| SMO254 (Super Austenitic Steel) | High resistance to pitting and crevice corrosion, saltwater resistant | High salinity wastewater treatment, corrosive liquid cooling systems |

| Titanium-Palladium Alloy | Enhanced acid corrosion resistance | Extremely acidic wastewater |

🎯 Key considerations when selecting materials

✅ Sewage composition → Acidity, salt content, suspended particles

✅ Operating temperature → High-temperature sewage requires high-temperature resistant materials

✅ Pressure requirements → High-pressure systems require high plate strength

✅ Is it prone to scaling or corrosion → Choose titanium get excellent corrosion resistance

✅ Frequency and cost of later maintenance

——

The operating condition (water composition, temperature, solid content, corrosiveness, pressure requirements, etc.) of the sewage purification system is complex and changeable. JINFAN provides complete customized heat exchange solutions. Whether a small sewage treatment plant, a large municipal sewage treatment plant, or an industrial wastewater treatment system, we can customize an efficient, reliable, and easy-to-maintain heat exchange system for you to maximize the overall process efficiency.

A 100,000 tons/day sewage treatment plant introduced our plate heat exchanger solution

Project background

The sewage treatment plant has a daily treatment capacity of 100,000 tons, mainly treating urban domestic sewage and some industrial wastewater. To improve sewage treatment efficiency, reduce energy consumption, and optimize the energy recovery system, the customer decided to carry out technical transformation of the original heat exchanger system.

Existing problems

❓ The original equipment has low heat exchange efficiency and high steam consumption

❓ The sludge digestion system has insufficient energy recovery and utilization, and the biogas production is low

❓ Frequent equipment maintenance leads to high operating costs

Solution

Based on the actual working conditions of the plant's sludge concentration-anaerobic digestion heat recovery, our company has tailored a plate heat exchanger overall solution:

✅ The highly efficient and detachable plate heat exchanger series is used, with a modular design for easy cleaning and maintenance

✅ For the sludge heating system, 316 stainless steel phe plates are used, taking into account both corrosion resistance and economy

✅ In the effluent and biogas slurry systems, energy recovery heat exchange stations are added to significantly increase the heat energy reuse rate

With years of industry experience, JINFAN offers more efficient structural designs and customized, reliable thermal solutions than traditional heat exchangers for wastewater treatment processes with specific conditions (such as corrosiveness and particulate matter content). Our uniquely designed plate heat exchangers can transfer a large amount of heat energy in a very small volume, ensuring that the critical temperatures required in the wastewater treatment process can be quickly and accurately reached and maintained. Our unique plate flow channel design effectively reduces particulate matter retention and deposition, lowering the risk of equipment blockage. Using plate heat exchangers to extract heat from warm wastewater discharged from the plant, and then reusing the recovered heat in processes such as sludge digestion, preheating influent, or plant heating, achieves efficient recycling and significantly reduces external energy consumption.

Get a High-efficiency Thermal Solution

Removable for easy maintenance and inspection. We offer hundreds of plate types, multiple materials, and multiple gasket models.

Specially designed and manufactured for liquid evaporation, the special flow channel design can achieve extremely high heat transfer efficiency.

The unique wide flow channel design can easily handle media containing particles, fibers, pulp or high-viscosity liquids.

Without any gaskets, the risk of leakage is eliminated. It is widely used in the highest temperature, pressure and strong corrosiveness.