Looking for plate condenser? Then JINFAN is just right.

We are a first-class plate type condenser manufacturer & supplier. A plate and frame condenser is a heat exchanger designed for the condensation of vapor into a liquid. It consists of plates with channels through which the vapor flows, facilitating efficient heat transfer and condensation. Plate heat exchanger condensers are widely used in various industrial applications and offer advantages such as compact size, high heat transfer efficiency, and easy maintenance.

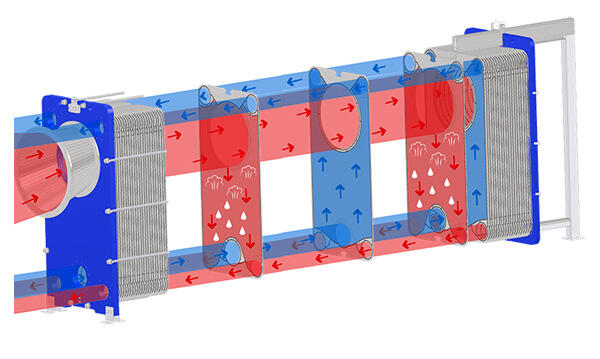

A plate type condenser is a heat exchange device designed specifically for evaporation or distillation systems operating under vacuum conditions. Plates are manufactured using a semi-welded process and then combined with gaskets to form independent flow channels. High-temperature steam condenses within the welded channels, while the cooling medium flows through the gasket channels, achieving fluid condensation through indirect heat exchange. The steam inlet and outlet are designed with a "large inlet, small outlet" design to facilitate rapid condensate discharge.

Plate type condensers are often used in conjunction with plate evaporators and are widely used in multi-effect concentration systems (such as triple-effect concentration). Their excellent heat transfer efficiency, small footprint, and ease of maintenance have made them widely used in industries such as sugar refineries, alcohol and juice concentrates, food and beverage processing, pharmaceuticals, chemicals, power generation, and shipping, making them an ideal alternative to traditional shell-and-tube condensers.

The heat transfer area of phe condenser is constructed from a series of corrugated plates, secured together by a frame plate and a pressure plate to ensure the equipment can withstand the design pressure. The plates are sealed using alternating laser welding and gaskets. It features a unique porthole configuration specifically designed for vacuum condensation, where steam condenses into liquid within the welded channels. Cooling water flows through the gasketed channels, indirectly exchanging heat with the steam within these channels.

The channel gaps of phe condenser are asymmetrical, with larger gaps on the steam side (welded channels) to minimize pressure loss during condensation. Smaller gaps on the cooling water side (gasketed channels) enable higher cooling water flow rates and generate strong turbulence, improving heat transfer coefficients and reducing the risk of scaling.

This design maintains low pressure drop on the steam side while achieving high heat transfer efficiency on the cooling water side. This combination significantly improves condensation speed and equipment operational stability, while also extending cleaning intervals.

JINFAN‘s strong technical team provides custom design solutions for plate and frame condenser system according to different cooling capacities and operational conditions. Our company focuses on creating energy-efficient designs, uses high-quality materials, such as stainless steel, titanium, and corrosion-resistant alloys that ensure optimal performance and efficiency for each unique application. We also provide modular condenser heat exchangers that are expanded by adding more plates to accommodate increased capacity or modified to suit changing process requirements.

When choosing a plate type condenser manufacturer, it's important to consider the experience in the relevant industry, the quality of designs, and the ability to provide comprehensive after-sales support to ensure long-term system performance. Jinfan has nearly 30+ years of experience in designing and manufacturing plate heat exchanger. We specialize in designing, producing, and supplying gasketed, welded, evaporator and condenser heat exchangers. Our condenser heat exchangers are commonly used in Marine, Chemical Industry, Petrochemical Power, Biopharmaceutical, etc.

"Replacing the traditional shell-and-tube condenser with your condenser heat exchanger, significantly reduced energy consumption, improved heat exchange efficiency, and saved a significant amount of space."

"The condensing efficiency remains stable even under high loads, and cleaning and maintenance are much easier than with the old equipment."