Looking for a plate type evaporator? Then JINFAN is just right.

We are a first-class gasketed phe evaporator manufacturer & supplier. A plate type evaporator is a heat exchanger designed for the evaporation of a liquid. It consists of plates with channels through which the liquid flows, facilitating efficient heat transfer and evaporation. Plate type evaporator is widely used in various industrial applications and offer advantages such as compact size, high heat transfer efficiency, and easy maintenance.

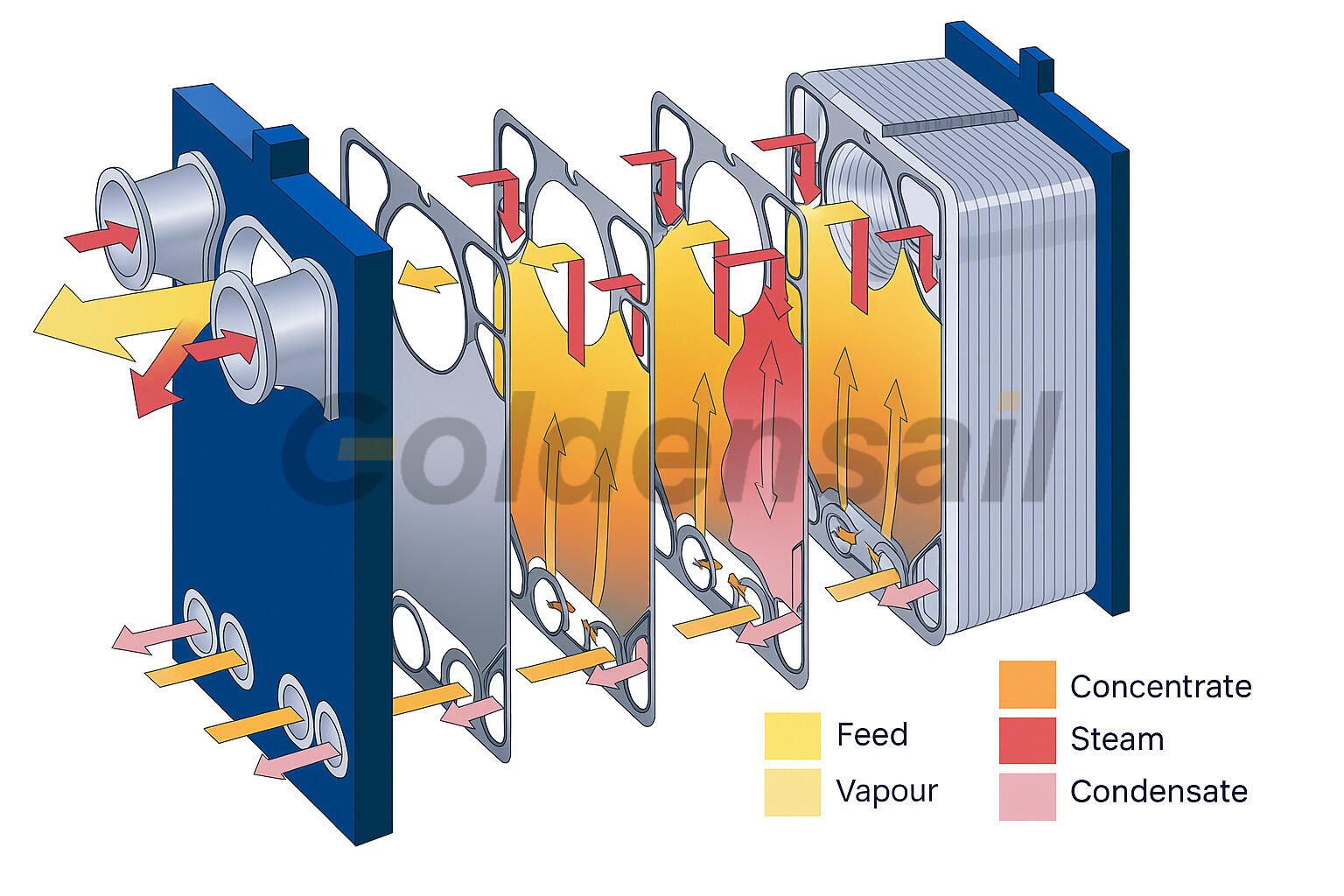

The plate evaporator is specifically designed for evaporation heat exchanger processes. PHE evaporator utilizes a semi-welded structure, with precision-pressed corrugated plates that direct the heating medium and the liquid to be evaporated into separate flow channels. This design significantly increases the heat transfer surface area and promotes strong turbulence in the fluid, achieving highly efficient heat transfer and phase change far exceeding traditional shell-and-tube evaporators.

A plate type evaporator consists of a series of semi-welded plates with channels for the fluid to flow through.. The heated liquid passes through the channels, and it vaporizes, transferring heat to another fluid or the surrounding environment. The plates in an evaporator heat exchanger are typically made of stainless steel or other corrosion-resistant materials. They are arranged in parallel or counterflow to maximize heat transfer efficiency. The special corrugated design on the plate surface not only generates strong turbulence, destroys the boundary layer, and improves heat transfer efficiency, but its asymmetric channel gap design also minimizes pressure drop and reduces the risk of scaling.

In operation, the liquid to be evaporated is introduced into the gasketed plate evaporator and flows through the channels between the plates. Heat is supplied to the plates, either through direct contact with a heating medium or by indirect heat transfer through a separate fluid. As the liquid flows through the channels, it absorbs heat and undergoes evaporation, producing vapor.

The vapor exits the phe evaporator, while any remaining liquid is drained. The vapor can be further processed or condensed to recover the evaporated substance. The compact design of evaporator heat exchangers allows for efficient use of space and easy integration into existing systems.

JINFAN Plate type Evaporator is based on semi-welded technology tailored to meet the specific needs of industries like food and beverage, pharmaceuticals, chemicals, and more. Our gasketed plate evaporators can be designed for particular types of fluids (e.g., viscous liquids, high fouling substances) or specific thermal efficiency requirements. Also allowing clients to scale the system as needed. Focus on energy efficiency, designing systems that minimize heat loss and optimize heat recovery. Use corrosion-resistant materials like stainless steel or titanium for the plates, ensuring durability and reliability, especially when handling aggressive or high-temperature fluids. Our plate is specially designed for evaporation systems to ensure optimal performance, maximum uptime and easy maintenance.

As a leading plate evaporator manufacturer invest in R&D to innovate and improve the performance of their products. We offer a large range of plate and gasket types to ensure the top performance of your equipment throughout its life cycle. When selecting a flat plate evaporator manufacturer, it's important to consider factors such as industry-specific experience, customization options, and service offerings to ensure the best match for your needs.

For information about our complete service offering, please feel free to contact us

Plate type Evaporator Spare Parts Materials

| Component | Material |

|---|---|

| Heat transfer plates | 316/316L, Ti, TiPd, Hastelloy, etc. |

| Field gaskets | NBR, EPDM, FKM, VITON, etc. |

| Flange connections | Carbon steel, Stainless steel, etc. |

| Pipe connections | Stainless steel, Titanium |

| Frame and pressure plate | Carbon steel, Epoxy painted |

Optimized Efficiency

✅ The large-surface corrugated plate design and optimized port configuration ensure maximum heat exchange efficiency. Our flat plate evaporator operates at lower temperature gradients, resulting in significantly reduced energy consumption.

Compact Semi-Welded Construction

✅ Our plate type evaporator compact footprint saves up to 70% space compared to shell-and-tube evaporators of comparable capacity. Easy Maintenance The modular construction allows for quick disassembly for inspection and cleaning.

Flexible Configuration

✅ The plate type, material, and connection method can be customized to your process. The modular design also allows you to easily adjust the number of plates as needed, adjusting the capacity.

Safety and Reliability

✅ High-quality materials (including stainless steel, titanium, Hastelloy, and other alloys suitable for corrosive applications) and stringent manufacturing standards provide a reliable, leak-proof solution that complies with international standards such as FDA and SGS.

"We replaced old shell-and-tube evaporator with your evaporator heat exchanger, resulting in a significant energy-saving effect. Cleaning downtime has been cut in half."

"The customization service was excellent. Our flat plate evaporator is perfectly suited to handle our highly corrosive process fluid, and performance has been stable for over a year."