Looking for a wide gap plate heat exchanger? Then JINFAN is just right.

We are a first class plate heat exchanger manufacturer & supplier. JINFAN free flow heat exchanger minimizes clogging and maximizes process uptime easily. With thousands of WideGap units saving energy for customers across the globe, we're making a real difference in sustainable energy solutions.

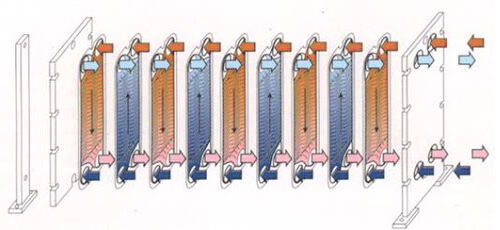

The gasketed plate type heat exchanger consists of a series of corrugated plates assembled between fixed cover and movable cover, retaining the design pressure. These phe plates can be made from different metals, including stainless steel, titanium, etc. Gaskets are used between the plates to prevent leakage. The counter-flow design allows for higher thermal performance and very close temperatures.

wide gap heat exchanger heat transfer

Wide Gap Plate Heat Exchanger, also known as Free Flow Plate Heat Exchanger, has ample spacing between plates enabling the seamless passage of fibers and particles through the heat exchanger, minimizing the risk of clogging. Because of the heat exchanger plate pattern and pressing depth design, these fluids flow easily through the heat exchanger. The corrugation of the plates provides the passage between the plates, supports each plate against the adjacent one and enhances the turbulence, resulting in efficient heat transfer. Depending on the duty, Wide Gap GPHE can be configured either with wide-wide or wide-narrow channels. These unique heat-transfer devices were first designed to provide maximum efficiency in transferring heat from one liquid to another or from steam to liquid.

JINFAN Wide Gap plate heat exchanger is the perfect solution for processing thick, fibrous, viscous, coarse, dirty, rough, crude, and clumpy fluids. Its wide plate gaps allow fibers and particles to pass through, minimizing clogging and maximizing process uptime easily. High flow turbulence between plates results in higher heat transfer efficiency; however, the consequence is a pressure drop. Our thermal design engineers can design the right heat transfer solution for your needs, providing maximum efficiency while minimizing pressure drop. From manufacturing to food processing, thousands of WideGap units are helping our customers worldwide achieve significant energy savings.

wide gap heat exchanger plate

In the future, if process requirements change, Wide Gap type can easily adjust the heat exchange area to meet different flow and temperature requirements.

free flow plate heat exchanger

✅ With a compact design, the occupation area can be decreased

✅ With a wide gap flow, it can heat the cold stream to a temperature very close to that of the entering hot stream

✅ Longer service intervals due to minimized clogging

✅ Easily optimize performance by reconfiguring plates to suit new operating conditions

"Changing JINFAN wide-gap PHE for our sugar refinery effectively solved the problem of frequent dirt in the impurity removal process during sugar production, significantly reducing downtime for maintenance."

"After using the wide gap plate heat exchanger, the frequent blockage problem was solved. The equipment still maintained good heat exchange performance under high load operation.."