Plate heat exchangers are popular due to their high efficiency and compact design, but their limitations cannot be ignored in certain specific scenarios. Here are their main drawbacks for your consideration:

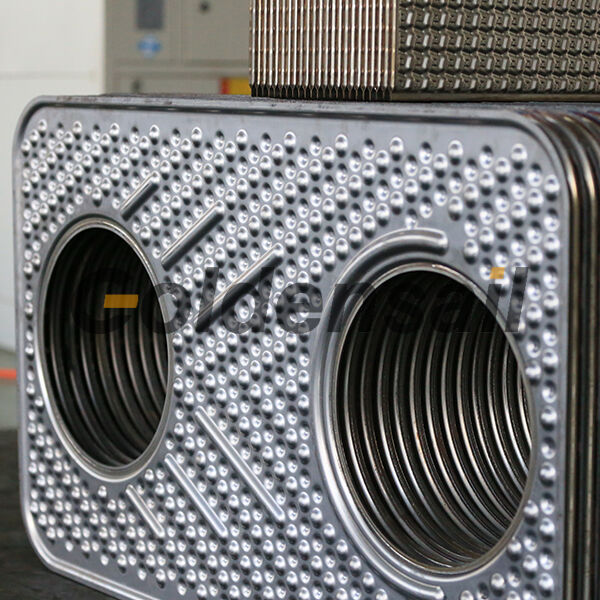

The design principle of Plate Heat Exchangers is "to achieve the largest heat exchange area with the least amount of material". The upper limits of pressure and temperature for plate heat exchangers are much lower than shell and tube heat exchangers. Gasket plate heat exchangers rely on rubber gaskets for sealing. These polymer materials harden, age, and lose elasticity under sustained high temperatures, eventually leading to seal failure. To achieve high heat transfer efficiency, the plates are typically very thin. Although the corrugated molding provides some structural rigidity, it is inherently inferior to thick-walled heat exchange tubes.

JINFAN Offers Fully welded or Semi-welded Plate Heat Exchangers. Utilizing laser welding technology instead of rubber gaskets and high-strength stainless steel or special alloy plates, it increases design pressure and extends the temperature range, easily handling harsh operating conditions.

Learn more

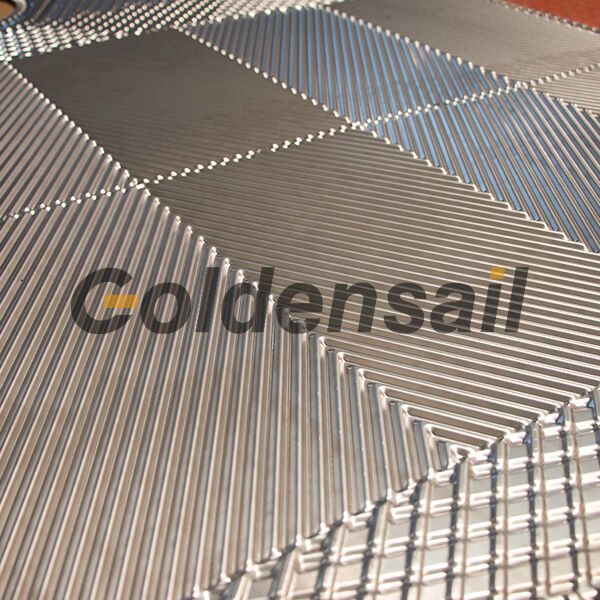

Plate heat exchangers boast unparalleled compactness and high efficiency, stemming from a complex and miniature network of flow channels formed by densely packed corrugated plates. However, this design philosophy also introduces a significant operational weakness: extremely stringent requirements for fluid purity, making them highly susceptible to blockages due to media issues, leading to a series of operational and maintenance challenges. In industries such as papermaking, textiles, and food processing, the media may contain fibers, dander, or plant residues. The blockage prevented heat exchange and caused uneven flow distribution. The system flow rate cannot meet the process requirements.

JINFAN Plate Heat Exchanger is designed specifically for dirty media. The Wide Gap Plate Heat Exchanger smoothly handles liquids containing fibers, crystals, or fine particles, such as pulp, sugar solutions, and sludge, significantly reducing the risk of clogging and cleaning frequency.

Learn moreThe core of a plate heat exchanger's removable and easily maintainable design relies on a ring of elastic sealing gaskets around its perimeter. While this design brings convenience, it also introduces an inherent weakness and a continuous maintenance burden. Gaskets are key determinants of the overall equipment's sealing reliability, safety, and total lifecycle cost. PHE Gasket performance essentially reflects the stability of its polymer material under specific operating conditions. Failure factors include thermal aging, chemical corrosion, and permanent deformation.

JINFAN offers a selection of top-tier phe gaskets, including EPDM and FKM, etc., providing superior chemical resistance and longer lifespan for high temperatures, oils, and highly corrosive media (such as acids, alkalis, and organic solvents). We also support online replacement designs, reducing downtime.

Learn more

The high efficiency of plate heat exchangers relies heavily on the high turbulence they generate within narrow flow channels. However, this advantage is severely weakened, even turning into a significant disadvantage, when dealing with high-viscosity fluids, posing serious challenges to their economic viability and applicability. High-viscosity fluids possess strong internal friction, which greatly suppresses their turbulence. Under laminar flow and low flow rate conditions, if the hot-side temperature is not properly controlled, the high-viscosity fluid near the plate surface may overheat locally due to poor heat exchange, forming solid fouling that is difficult to remove.

JINFAN Plate Heat Exchanger features a more specialized plate corrugation angle and depth design, along with an asymmetric flow channel configuration, providing customized low-resistance flow channels for high-viscosity fluids. Simultaneously, we can precisely calculate and match pump power to ensure optimal efficiency and energy consumption balance in heat exchange processes involving media such as asphalt, resin, and high-concentration pharmaceutical solutions.

Learn morePlate heat exchangers are the undisputed efficiency champion in liquid-liquid heat transfer, but their flow channel structure faces severe challenges when dealing with complex heat and mass transfer processes involving the gas phase or phase changes (condensation, evaporation). Although such functions can be "achieved" through multi-flow and multi-stage combinations, their efficiency, stability, and economy are often difficult to match with dedicated equipment. Essentially, it is forcibly applying a highly efficient model suitable for continuous liquid phases to multiphase flow fields.

JINFAN Offers dedicated plate evaporator/condenser models. Utilizing plate textures optimized for phase change processes, it ensures uniform distribution of the gas phase medium and efficient liquid phase discharge. Our multi-stage integrated design integrates preheating, evaporation, and superheating functions into a compact frame, achieving efficiencies comparable to or even exceeding some shell-and-tube equipment.

Learn more

The core heat transfer element of a plate heat exchanger—the metal plates—despite precision pressing and material selection, still faces continuous threats to its integrity in harsh industrial environments. Plate perforation, i.e., tiny holes in the plates due to corrosion, wear, or fatigue, is the most serious and highest-risk type of potential failure in plate heat exchangers. For processes handling media that are strictly incompatible with each other, this is not merely equipment failure, but a fundamental design risk that could trigger a crisis across the entire safety, environmental, and production chain.

JINFAN Plate Heat Exchanger: For media that are strictly incompatible (such as pharmaceuticals and fine chemicals), we offer the Double Wall late-layer Heat Exchanger. When the first layer plate is accidentally perforated, the leaked medium will flow out through the safety monitoring hole between the two layers and trigger an alarm, ensuring absolute isolation and providing double protection for safe production.

Learn moreA core economic advantage of plate heat exchangers lies in their ability to achieve high heat exchange efficiency with relatively low initial investment. However, this advantage heavily relies on one prerequisite: the use of conventional materials (such as 304/316 stainless steel). Once the process medium becomes highly corrosive, forcing an upgrade to high-grade metals like Ti or Hastelloy C-276, the cost structure will undergo a drastic, even disruptive, change. In some extremely corrosive environments, it may even be necessary to replace the carbon steel frame with a stainless steel coating or a solid stainless steel material, and the bolts may also need to be upgraded, further increasing costs.

JINFAN possesses mature special metal processing capabilities (titanium, nickel, SMO 254, Hastelloy). By optimizing the plate structure design, we maximize material utilization and reduce waste while ensuring corrosion resistance and strength. Simultaneously, we offer mixed-material assembly solutions for plates (such as titanium on one side and stainless steel on the other) for targeted corrosion protection, achieving the optimal cost configuration.

Learn more

If you are facing the following challenges

Dirty, fouling, or corrosive media

Operating pressure or temperature close to or exceeding normal ranges

Stringent requirements regarding leakage risk and maintenance costs

Please contact us. Our engineers will conduct a detailed operating condition analysis and

provide customized plate heat exchanger solutions to help you find the perfect balance between efficiency, safety, and total cost of ownership.