100% Compatible with all main brands worldwide

A large quantity of goods in stock for immediate delivery

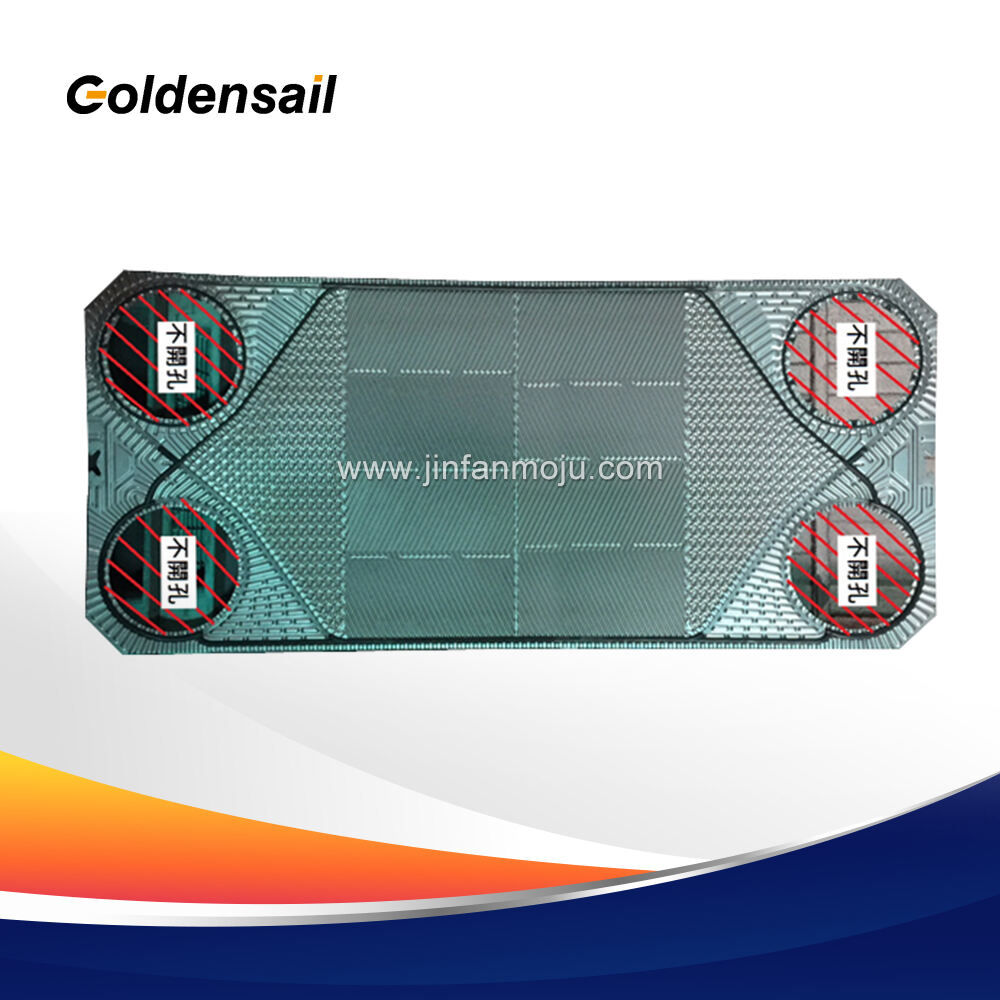

High-quality raw materials and precision mold technology ensure that the plate heat exchanger plates and gaskets have excellent durability and stable performance. If your plate heat exchanger leaks, pressure drops or the flow rate decreases, it may be time to replace your parts.

| Component | Material | Corrosion Resistance | Typical Application / Medium | Ref. Temp. Range |

|---|---|---|---|---|

| Plates | Stainless Steel 304 | Fair (chloride sensitive) | Fresh water, HVAC systems | -40 ~ 250°C |

| Stainless Steel 316 / 316L | Good (chloride resistant) | Seawater desalination, food, mild chemicals | -40 ~ 300°C | |

| Titanium | Excellent (marine grade) | Seawater, brine, marine cooling | -200 ~ 300°C | |

| Nickel Alloy (Hastelloy) | Outstanding (acid resistant) | Sulfuric acid, hydrochloric acid | -50 ~ 450°C | |

| Carbon Steel (coated/lined) | Poor (needs coating) | Oil, thermal oil (non-acid) | -20 ~ 400°C | |

| Gaskets | NBR | Fair (not for strong oxidizers) | Water, mineral oil, air | -30 ~ 120°C |

| EPDM | Good (not for mineral oil) | Hot water, steam, some refrigerants | -40 ~ 150°C | |

| FKM / Viton | Excellent (oil & solvent resistant) | Oils, fuels, mild acids/bases | -20 ~ 200°C | |

| PTFE | Excellent (near-inert) | Strong acids, bases, solvents | -200 ~ 260°C |

FAX30B Heat Exchanger Plate & Gasket | AL Replacement Spare Parts Manufacturer

FAX30BW Heat Exchanger Plate & Gasket | AL Replacement Spare Parts Manufacturer

FMA30W Heat Exchanger Plate & Gasket | AL Replacement Spare Parts Manufacturer

FMX25B Heat Exchanger Plate & Gasket | AL Replacement Spare Parts Manufacturer

FMX25M Heat Exchanger Plate & Gasket | AL Replacement Spare Parts Manufacturer

UX80 Heat Exchanger Plate & Gasket | Hisaka Replacement Spare Parts Manufacturer

UX90 Heat Exchanger Plate & Gasket | Hisaka Replacement Spart Parts Manufacturer

FT20M FT40M FT50M Heat Exchanger Plates and Gaskets Replacement

FM3 FM6 FM10 FM15 FM30 FMx25 Heat Exchanger Plates and Gaskets Replacement