The Plate Heat Exchangers are integral to chemical processing, enabling efficient heat transfer across a range of applications. They facilitate the cooling of hot liquids and the heating of cold ones, and effective temperature management of corrosive liquids or condensation.

Chemicals play a pivotal role in numerous aspects of our daily lives, contributing to advancements in various fields and enhancing our quality of life. In agriculture, fertilizers and pesticides help boost crop yields, ensuring food security for growing populations. Pharmaceuticals, derived from chemical compounds, play a crucial role in treating diseases and enhancing healthcare outcomes. Additionally, they play a vital role in energy production, including the refining of fossil fuels and the development of renewable energy sources.

Most chemical plants work under continuous processes where the need for a reliable heat exchanger is paramount. While traditional shell-and-tube heat exchangers are widely used, they can no longer fully meet the increasingly stringent demands of modern chemical industry in terms of heat transfer efficiency, anti-scaling, corrosion resistance, high/low temperature and high pressure resistance, and compactness. Consequently, the chemical industry is increasingly adopting new, efficient, compact, and corrosion-resistant heat exchange equipment (such as fully welded plate heat exchangers and plate and shell heat exchangers) to replace traditional heat exchangers and meet the challenges of complex media and extreme operating conditions.

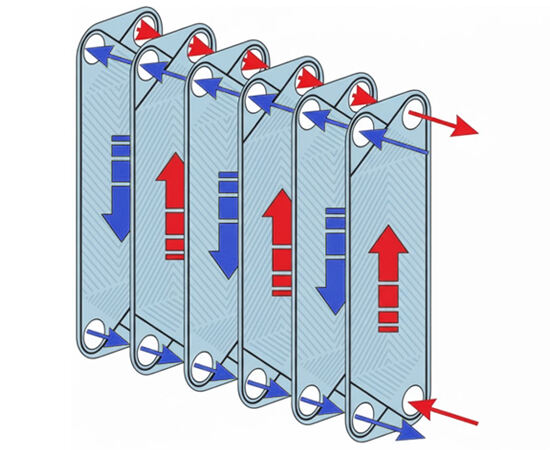

The unique plate corrugations of plate heat exchangers generate high turbulence, resulting in higher heat transfer coefficients and smaller equipment. Plates are available in a variety of metals (stainless steel, titanium, Hastelloy, etc.) to handle a variety of corrosive media. Gasketed plates offer easy disassembly and cleaning, simplifying maintenance, and allow for adjustable plate sizes to accommodate varying processing capacities. Welded plates withstand higher pressures and temperatures, making them suitable for demanding applications. Plate frame heat exchangers are widely used in the chemical industry due to their high heat transfer efficiency, compact design, and ease of expansion and maintenance.

Get in touchPlate type heat exchangers for heating or cooling process fluids; widely used in heat recovery systems to preheat feedstock or generate steam, improving overall energy efficiency. Use corrosion‑resistant materials when handling acids. Fully welded or semi‑welded designs for high pressure/temperature resistance. Semi‑welded types are effective for phosphoric acid concentration, handling viscous/scaling media as reboilers or evaporators.

Material selection is crucial for cooling/heating acidic or alkaline solutions due to corrosiveness. For high‑pressure and high‑temperature operations, fully welded plate heat exchangers (including plate & shell designs) are preferred for durability and reliability. Used in electrolysis to cool electrolytes and maintain reaction temperatures. Plate condensers condense steam under vacuum—suitable for small power plants or bioethanol applications. In hydrogen production, exchangers cool electrolytes and gases for transport and storage.

Plate type heat exchangers heat and cool organic solvents, intermediates, and oils. They are applied as reboilers, condensers, and in distillation, evaporation, and polymerization units to precisely add or remove heat. Plate condensers enable solvent recovery from organic vapors. Wide‑gap plate heat exchangers suit high‑viscosity or scaling‑prone media. Custom material and plate pattern choices help balance fouling resistance and thermal performance.

| Feature | Gasketed Plate Heat Exchanger (Gasketed PHE) |

All-Welded Plate Heat Exchanger (All-Welded PHE) |

Plate and Shell Heat Exchanger (Plate-and-Shell HE) |

|---|---|---|---|

| Structure | Consists of a series of corrugated metal plates sealed with gaskets and clamped together with a frame and bolts. | Plates are fully welded or laser welded without gaskets, or with minimal gaskets only at fluid inlets and outlets. | A circular or square plate pack is installed inside a cylindrical shell, with heat transfer between plate side and shell side. |

| Sealing Method | Elastic gasket sealing | Welded sealing (completely or almost gasket-free) | Combination of welded sealing and flange sealing |

| Maximum Pressure | Low (typically < 2.5 MPa) | High (up to 6.0 MPa or higher) | High (up to 10 MPa or higher) |

| Maximum Temperature | Low (depends on gasket material, typically < 200 °C) | High (up to 450 °C or higher) | High (up to 500 °C or higher) |

| Heat Transfer Efficiency | Very high (full counter-current flow, high U-value) | High | High (multi-pass design) |

| Leak Tightness | Relatively low (gaskets may fail under high temperature, pressure, or corrosion) | Very high (suitable for toxic, flammable, or explosive media) | Very high (fully welded plate pack) |

| Cleaning & Maintenance | Easy (can be disassembled for mechanical cleaning) | Difficult (chemical cleaning only) | Difficult (non-detachable plate pack, chemical cleaning only; shell side can be mechanically cleaned) |

| Media Limitation | Suitable for non-corrosive, clean fluids under mild conditions. | Suitable for high-temperature, high-pressure, and highly corrosive fluids. | Suitable for applications with large flow or phase change on one side (shell side), under high pressure. |

| Typical Applications | Cooling of fluids, mild heat recovery, and utility systems (e.g., cooling water). | Cooling of high-temperature and high-pressure chemical products, heating/cooling of corrosive media (e.g., sulfuric or nitric acid). | High-pressure gas cooling, steam condensation, and heat transfer in large-scale, high-flow systems. |

With excellent craftsmanship, innovative plate design, and the best materials available, JINFAN's high-temperature and high-pressure plate frame heat exchanger maintain their integrity in the most demanding chemical manufacturing. With 30+ years of experience in Plate-type Heat Exchangers, JINFAN has become a thermal solution expert of Plate Heat Exchangers. We drive innovation by leveraging profound knowledge, blending it with state-of-the-art technology, and drawing from a wealth of specialized expertise.

Have a specific need? Get in touch with JINFAN or send Email [email protected]

Removable for easy maintenance and inspection. We offer hundreds of plate types, multiple materials, and multiple gasket models.

Specially manufactured for phase change processes such as steam condensation, achieves extremely high heat recovery.

Specially designed and manufactured for liquid evaporation, the special flow channel design can achieve extremely high heat transfer efficiency.

Ideal for high pressure and corrosive media. We have various specifications of welded plate bundles.

The heat exchanger plate is made of a metal material with excellent corrosion resistance, handle heat exchange processes involving corrosive media

The unique wide flow channel design can easily handle media containing particles, fibers, pulp or high-viscosity liquids.

Without any gaskets, the risk of leakage is eliminated. It is widely used in the highest temperature, pressure and strong corrosiveness.