Explore efficient heat exchange solutions for District Heating Systems, get product selection, technical support, and case studies to instantly improve your system performance!

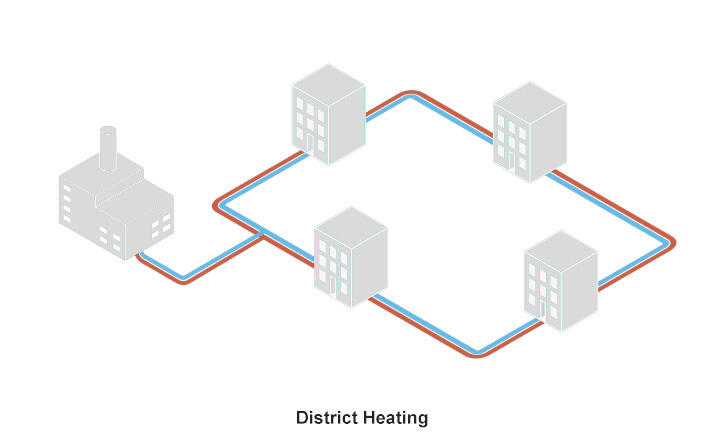

The District Heating System distributes heat through pipes. Heat energy generated by a heat source is transported to users via an insulated pipe network as hot water or steam for building heating, domestic hot water, and some industrial heating needs. Heat sources can come from a variety of sources, including coal-fired and gas-fired boilers, geothermal energy, biomass energy, industrial waste heat, and combined heat and power systems, enabling efficient energy utilization and diversified supply. The District Heating System primarily replaces decentralized heating, reducing energy waste and environmental pollution, improving thermal energy efficiency, and reducing carbon dioxide and pollutant emissions. District Heating also facilitates unified management and maintenance, enhancing the intelligence and safety of urban energy management.

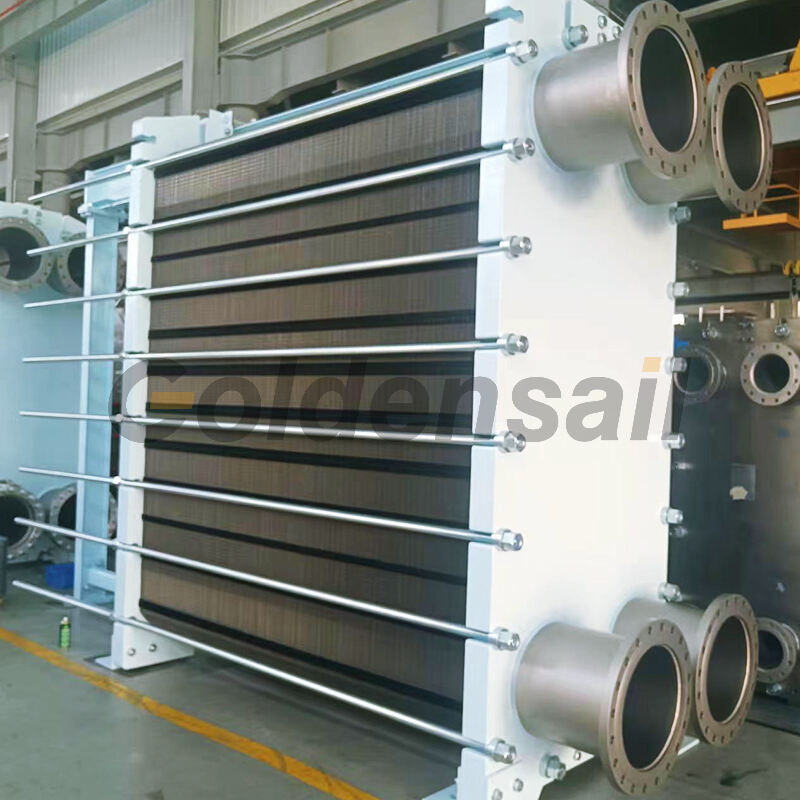

The plate heat exchanger is a heat exchange device consisting of corrugated plates, sealing gaskets, fixed and movable pressure plates, clamping bolts, and a support frame. The plates feature a special corrugated design that enhances fluid turbulence, improves heat transfer, and ensures device strength. Sealing gaskets are embedded around the plates to guide the alternating flow of hot and cold fluids and prevent mixing, ensuring reliable sealing. Fluids at different temperatures flow in adjacent channels, transferring heat through the plates without direct contact. This method not only achieves efficient heat exchange but also ensures complete isolation between the media, preventing cross-contamination. Plate heat exchangers offer heat transfer efficiency 3 to 5 times higher than traditional shell-and-tube systems. They are compact, require minimal floor space, are easy to maintain, and can be easily disassembled for cleaning.

In district heating systems, plate heat exchangers connect the primary network (heat source side) and the secondary network (user side), ensuring efficient heat transfer while completely isolating the water quality and pressure on both sides. Not only does it enhance system safety and stability by preventing backflow of contamination from the user side, but it also enables flexible adjustment of heating parameters based on regional loads, thereby improving both energy efficiency and operational efficiency. Plate heat exchangers are a vital component in modern district heating systems.

1. Heat Exchange Station

This is the most typical application. Plate heat exchangers are installed in heat exchange stations to transfer heat from the heat source (primary network) to hot water supplied to the user (secondary network), while achieving complete isolation of water quality and pressure. This prevents impurities from the primary network from entering the user system, ensuring safe equipment operation and facilitating zoning management and maintenance.

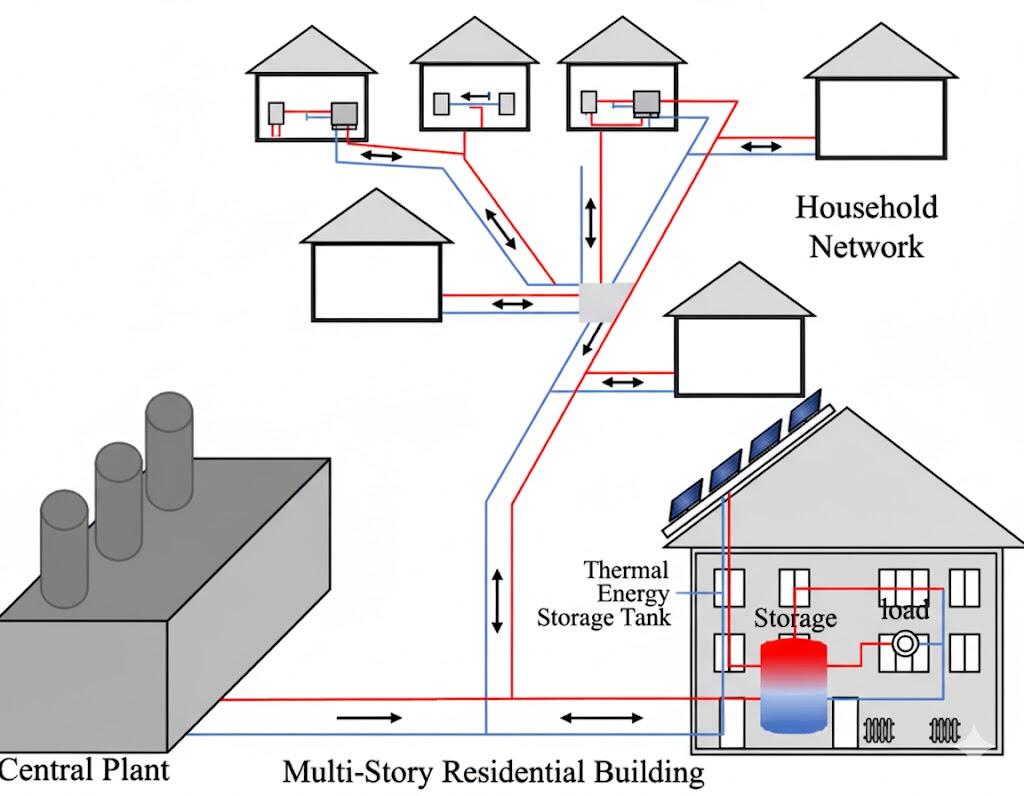

2. Independent Heat Exchangers for Buildings

In urban centralized heating systems, each building is equipped with an independent plate heat exchanger for secondary heat exchange, supplying hot water to indoor heating systems or domestic hot water systems. This arrangement facilitates household metering and temperature control, improving comfort and energy efficiency.

3. District Heat Exchange Stations in Heating Networks

For urban systems with a wide heating coverage, district heat exchange stations can be installed at intermediate nodes. Plate heat exchangers can be used to transfer heat in sections, reducing heat loss and increasing the flexibility and adjustability of the network.

4. Waste Heat Recovery and System Thermal Optimization

Plate heat exchangers can also be used to recover industrial waste heat, boiler exhaust heat, or waste heat from heat pump systems. This recovered low-grade heat can be reused in heating systems, achieving cascaded energy utilization and energy conservation and consumption reduction.

| Material | Abbreviation | Main Features | Advantages in District Heating | Suitable Conditions (Water quality / Temperature) | Cost |

|---|---|---|---|---|---|

| Austenitic Stainless Steel | AISI 304 | Good corrosion resistance and economical. | Suitable for primary networks of conventional district heating with relatively good water quality. | Clean, neutral water; primary side heat sources (e.g., power plant return water, neutral boiler water). | Low |

| Austenitic Stainless Steel | AISI 316 / 316L | Contains molybdenum; stronger resistance to chloride corrosion and pitting than 304. | Most commonly used material in district heating, especially suitable for secondary networks (user side) or slightly poorer water quality. | General water quality, especially where small amounts of chloride may exist (e.g., tap water makeup, non-fully softened water). | Medium |

| Titanium Alloy | Ti | Excellent corrosion resistance, extremely strong resistance to chloride-induced corrosion. | Suitable for interfaces using seawater, geothermal water, or high-salinity sources. Rare in urban district heating unless water quality is very poor. | High-chloride, corrosive media (e.g., some geothermal waters, seawater). | Very high |

| Hastelloy | Hastelloy | Extremely high resistance to acids, alkalis, chlorides and other corrosive media. | Used where special corrosion resistance is required, such as industrial waste heat recovery or special heat sources. | Strongly corrosive media. | Extremely high |

Note: choose material based on actual water chemistry, temperature and pressure conditions; cost refers to relative procurement and lifecycle expense.

Contact UsCalculate the required heat exchange area based on the system's heat load, flow rate, and inlet and outlet temperatures.

The primary network of a district heating system has high pressures and temperatures, so design parameters should match the operating conditions. For high-temperature and high-pressure systems, semi-welded or fully welded plate heat exchangers are recommended for safety and sealing.

The plate material should be selected according to the media properties, water corrosivity, and temperature conditions. Common materials include stainless steel (304, 316L), titanium, and nickel-based alloys.

The corrugation structure affects both heat transfer efficiency and fluid resistance. Select the appropriate corrugation angle and channel layout based on system flow rate, pressure drop limit, and media characteristics to ensure optimal performance.

For large heating plants or district-based exchangers, ease of disassembly and cleaning should be considered. Detachable plate heat exchangers are convenient for maintenance, while welded types are better for high-pressure and tight-sealing needs.

The system should have a certain adjustment margin for seasonal load fluctuations. Plate heat exchangers can flexibly adjust capacity by adding or removing plates for future expansion.

Besides initial equipment cost, operating energy consumption, maintenance intervals, spare parts costs, and long-term reliability should be considered to ensure the best overall investment return.

Enhancing efficiency, reliability and long-term sustainability

JINFAN is dedicated to the research, development, and manufacture of high-performance plate heat exchangers. Leveraging advanced manufacturing technology and rigorous quality control, we ensure the reliability of each product. We offer customized services, tailoring plate materials, gasket types, and flow configurations to your specific needs. Our professional technical team provides rapid response, spare parts support, and comprehensive after-sales service to ensure the safe and efficient operation of your system.

Get in touch

Removable for easy maintenance and inspection. We offer hundreds of plate types, multiple materials, and multiple gasket models.

Ideal for high pressure and corrosive media. We have various specifications of welded plate bundles.

Without any gaskets, the risk of leakage is eliminated. It is widely used in the highest temperature, pressure and strong corrosiveness.