Contact JINFAN engineering team to select the right plate pasteurizer, balancing thermal performance, hygiene, and operational cost.

Pasteurization is a thermal process that utilizes a specific combination of temperature and time to eliminate pathogens and reduce microorganisms, ensuring product safety, longer shelf life and keeping the original taste. Plate heat exchangers ( Plate Coolers ) are essential equipment of HTST systems, ensuring precise temperature control and energy efficiency. They are widely used in the processing of liquid foods such as milk, yogurt, juice, beer, and tea beverages. By heating raw materials to a moderately high temperature and maintaining it for a specific duration, pathogens are killed and spoilage bacteria are reduced, ensuring food safety and extending shelf life.

Get in touchThe Plate Heat Exchanger ( Plate Coolers ) is a highly efficient and compact heat exchange device. It transfers heat between two fluids through a series of corrugated metal plates. The corrugated design of the plates creates intense turbulence in the fluids, resulting in a heat transfer coefficient significantly higher than that of traditional shell-and-tube heat exchangers. This allows the hot and cold fluids to be brought very close to each other, making it suitable for processes requiring precise temperature control. It is particularly well-suited for heat recovery, achieving heat recovery rates exceeding 90%.

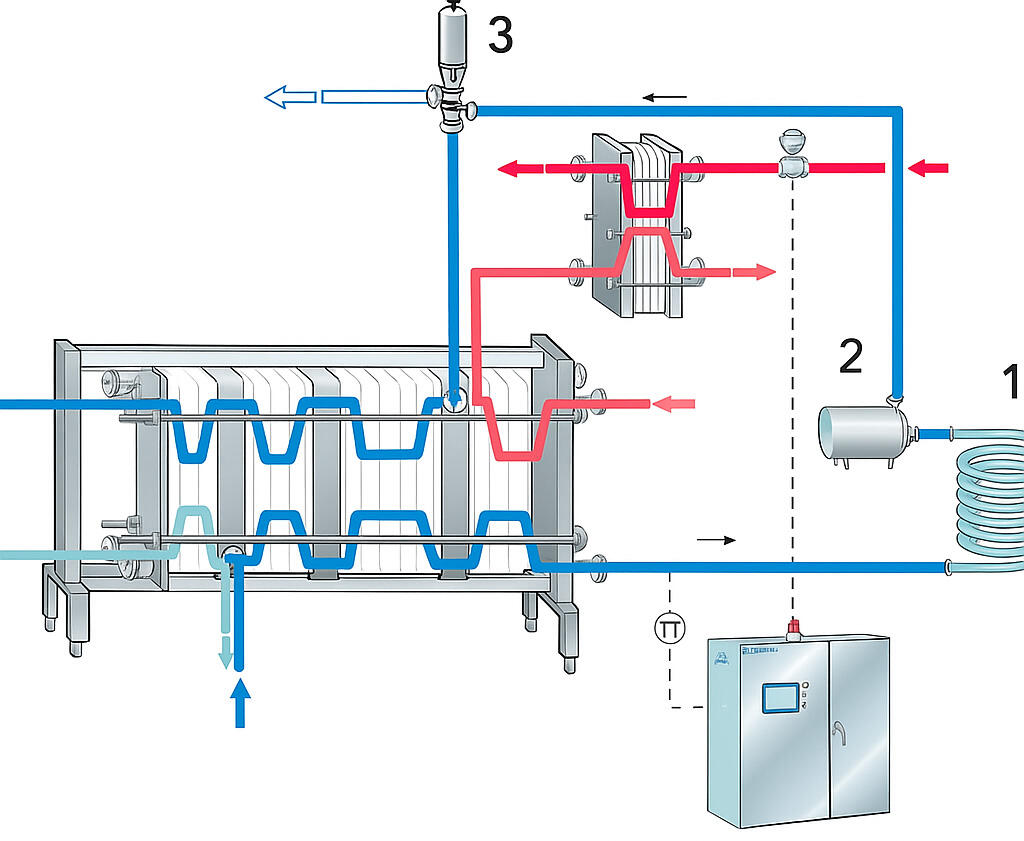

✅ Heat Recovery Section: Heat is exchanged between unpasteurized cold ingredients and pasteurized hot ingredients.

✅ Heating Section: The preheated ingredients are rapidly heated to the specified pasteurization temperature using an external heat medium. Cooling section: The sterilized and heat-insulated raw materials are quickly cooled to the temperature required for filling or storage through refrigerant or cooling water.

Plate Heat Exchangers' high heat recovery rate is its greatest advantage in pasteurization. The preheating and precooling processes are nearly 90% energy self-sufficient, significantly reducing operating costs. At the outlet of the holding section, if the material temperature falls below the set sterilization temperature, the control system immediately activates a diverter valve, automatically transferring the material back to the balancing tank for reprocessing, ensuring 100% sterilization compliance.

Ensuring Hygiene, Reliability, and Efficiency

Our plate pasteurizers are specifically engineered for dairy, juice, beer, and beverage applications, providing stable thermal performance and sanitary operation even under continuous high-load conditions. Each system is designed with optimized plate geometry and flow distribution, ensuring uniform heat transfer and preventing product burn-on or contamination. The regenerative section maximizes heat recovery between the hot and cold product streams, reducing energy consumption and operating costs by up to 90%.

Learn moreSelecting a plate pasteurizer is a critical task, directly impacting system productivity and project operating costs.

The following are key factors to consider when selecting a plate pasteurizer:

✅ Product Type and Viscosity

Low-viscosity liquids (milk, juice, tea) are suitable for gasketed plate heat exchangers. Viscous or granular media (yogurt, puree, sauce) may require wide-gap or semi-welded types to prevent clogging.

✅ Processing Capacity and Flow Rate

The plate area and channel design should be matched to your processing capacity to ensure stable heat transfer and minimized pressure drop.

✅ Heating and Cooling Temperature Requirements

HTST pasteurization typically involves heating the product to 72-75°C for 15-30 seconds, followed by rapid cooling. The plate configuration should be determined based on the inlet/outlet temperatures and the heating and cooling media.

✅ Energy Recovery System

A good plate pasteurizer can achieve regenerative heat recovery, saving up to 90% of heating energy, making it a key consideration for sustainable and cost-effective operation.

✅ Hygiene and Cleanliness Requirements

Choose high-quality stainless steel and FDA-compliant washers.

Recommended Pasteurizer Configurations

| Product Type | Recommended Pasteurizer Type | Key Features |

|---|---|---|

| Milk / Juice | Gasketed PHE | High heat recovery, easy cleaning (CIP), ideal for low-viscosity liquids |

| Beer / Carbonated Drinks | Semi-welded PHE | Gas-tight design, reliable sealing for carbonated media |

| Yogurt / Puree | Wide-gap PHE | Handles viscous fluids and particulates, reduced fouling risk |

| Soy Milk / Plant Drinks | Gasketed or Semi-welded | CIP-friendly, stable temperature control, corrosion-resistant options |

JINFAN offers one-stop solutions for heat transfer, from unique design to precision manufacturing. Our engineers are experts in thermal calculations and mechanical design! We design and manufacture Heat Exchangers that perfectly match your specific needs. Our expertise covers your heat exchange system all its requirements. JINFAN uses high-quality plates & gaskets, 100% compatible with your existing systems. Our products undergo rigorous testing to ensure excellent performance. Our strong inventory ensures timely delivery, guaranteeing a hassle-free experience.

As a leader in plate heat exchanger solutions, we’re committed to driving innovation in the dairy industry. Contact us to get high-performance heat exchange solutions! Let’s re-explore pasteurization technology together with its potential.

Removable for easy maintenance and inspection. We offer hundreds of plate types, multiple materials, and multiple gasket models.

Made of food-grade materials and designed without dead angles, it is of high standard and has zero risk of contamination.

Specially manufactured for phase change processes such as steam condensation, achieves extremely high heat recovery.

Specially designed and manufactured for liquid evaporation, the special flow channel design can achieve extremely high heat transfer efficiency.

Ideal for high pressure and corrosive media. We have various specifications of welded plate bundles.

Aimed at energy and high-end manufacturing, it is suitable for ultra-high pressure applications such as high-pressure hydrogen production.

The unique wide flow channel design can easily handle media containing particles, fibers, pulp or high-viscosity liquids.

Without any gaskets, the risk of leakage is eliminated. It is widely used in the highest temperature, pressure and strong corrosiveness.