Plate type Heat Exchanger is an industrial energy-saving device used to transfer heat between two fluids through a series of metal plates. These plates are typically made of stainless steel, titanium, or other materials that are corrosion-resistant and have good thermal conductivity. The fluids flow on opposite sides of the plates, allowing for heat transfer to occur as they pass by each other.

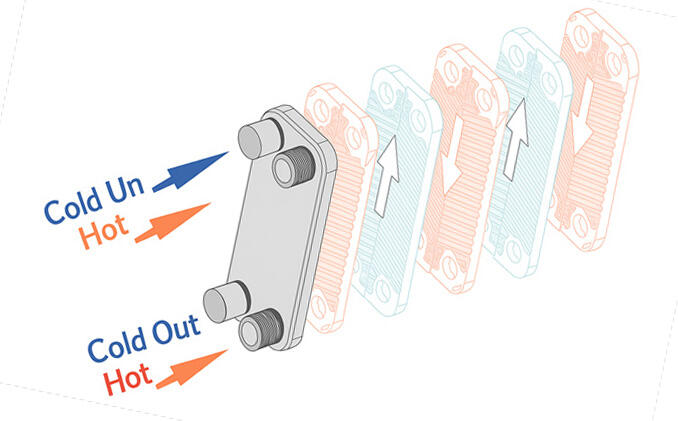

Plate heat exchangers consist of a number of corrugated metal plates, with a channel formed between each two plates. Hot and cold fluids flow alternately through these channels to transfer heat without direct contact. The hot fluid flows through the plates on one side, transferring heat to the plates; this heat is then transferred through the plates to the cold fluid on the other side of the plates. There are rubber gaskets on the edges of the plates to control the direction of the fluid and prevent leakage.

plate type heat exchanger working principle

✅ The design of plate heat exchangers allows for a large surface area for heat transfer to take place, making them highly efficient in transferring heat between fluids. This efficiency is further enhanced by the turbulent flow created by the corrugated plates, which helps to maximize heat transfer rates of the heat exchanger.

✅ The thin plates and close arrangement make the overall volume small and light. Under the same heat transfer capacity, the footprint of plate-type heat exchanger is greatly reduced, which is suitable for places with limited space.

✅ The detachable design makes the plate exchanger maintenance very convenient. You only need to loosen the clamping bolts to disassemble them piece by piece, which is convenient for inspection, cleaning or replacement of plates and gaskets of the heat exchanger.

✅ The efficient heat transfer performance reduces energy consumption and avoids excessive waste of raw materials. The plate heat exchanger can work at a lower temperature difference, improve energy utilization and reduce emissions.

✅ The number of plates of the heat exchanger can be flexibly increased or decreased according to the working conditions to meet different heat exchange requirements. This modular design makes the equipment highly scalability.

✅ The fluid has a short flow path in the channel between the phe plates, high flow rate, less heat loss, and improved overall heat exchange efficiency.

| Feature | Plate Heat Exchanger | Shell-and-Tube Heat Exchanger |

|---|---|---|

| Heat Transfer Efficiency | High (turbulence-enhanced) | Lower (mostly laminar flow) |

| Footprint | Compact | Large |

| Maintenance | Easy and quick | Complex, may require lifting or opening |

| Scalability | Flexible plates can be added or removed | Fixed not adjustable |

| Energy Efficiency | Excellent (operates at low temperature differences) | Average (requires higher temperature differences) |

As an efficient and compact heat exchange equipment, plate heat exchangers are widely used in multiple industries to meet the heat exchange requirements under different working conditions.

✅ used for heat exchange in the central air conditioning system of buildings to improve energy efficiency and save energy.

✅ plays a key role in the reaction process, cooling, heating and heat recovery, and adapts to corrosive and high temperature conditions.

✅ Used in power station circulating cooling system, lubricating oil cooling, water-water heat exchange, etc.

✅ Used in milk pasteurization, beer cooling, juice heating, etc., in line with hygiene standards.

✅ Meets cleanliness requirements, used for liquid heating, cooling and process heat recovery.

✅ Used for slurry heating, rinsing water recovery, dyeing liquid temperature control, etc.

✅ Applied to heat exchange tasks in marine conditions such as main engine cooling and fresh water generation systems.

Whether it is energy recovery, fluid cooling, or process heating, plate heat exchangers can provide efficient and stable heat exchange solutions.

JINFAN focuses on the research and development and manufacturing of plate heat exchangers, plates, gaskets, and heat exchanger accessories, including replacement parts for all main brands. We are committed to providing highly matched and customized heat exchange solutions for every industry. From core plates to key pads, all are independently produced to ensure fast delivery and stable quality.

👉 Contact us to get professional heat exchange solutions for your industry applications!

• Plate type Heat Exchanger Maintenance Guide

• Common Reasons of Plate Heat Exchanger Leakage

• Troubleshooting for Plate Heat Exchanger Leak

• Solutions of Plate Heat Exchanger Leakage Problems

• Plate Heat Exchanger vs. Shell and Tube