Jinfan plate type heat exchangers offer efficient and compact heat exchange solutions, helping Data Centers achieve precise temperature control.

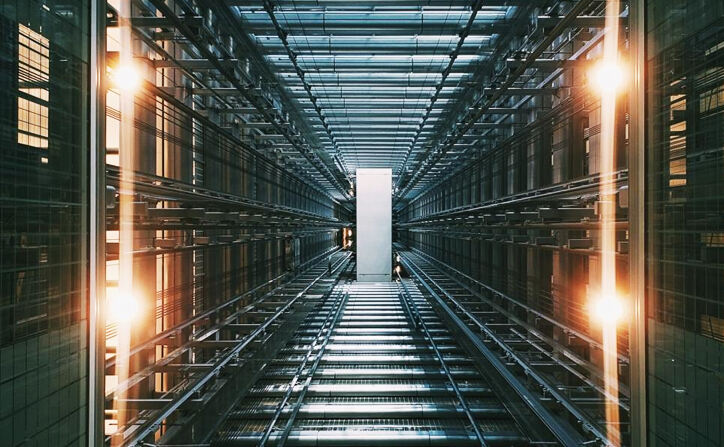

In data centers, almost 100% of the input electrical energy is ultimately converted into heat. A single high-performance server can consume hundreds or even thousands of watts. If this heat is not dissipated in time, it can lead to equipment overheating and malfunctions, system instability, and fire risks. Therefore, the main goals of data center cooling systems are precise temperature control, efficient heat removal, uniform airflow, high reliability, and maintainability.

Traditional air-cooled air conditioning systems have been the mainstream in data centers for the past few decades. Their core reliance is on mechanical compression refrigeration, a high-energy-consuming and high-emission model. Plate heat exchangers are a highly efficient and compact heat exchange device. A plate heat exchanger consists of a series of corrugated metal plates stacked together, forming two independent fluid channels. The circulating cooling water inside the data center (primary side) and the outdoor cooling medium (secondary side, usually water or ethylene glycol solution) exchange heat only through the plates, without direct contact. The corrugated plate design creates a huge heat transfer surface area and turbulence, resulting in extremely high heat exchange efficiency (typically over 90%), and the temperature difference between the two sides can be very small (only 1-3°C).

✅ The compact design of plate heat exchangers is ideal for space-constrained data center environments and allows for resource expansion.

✅ The high heat transfer efficiency of plate heat exchangers can better handle the high-density heat loads of servers, reducing overall system energy consumption.

✅ The structure of plate heat exchangers prevents cross-contamination of fluids on both sides, protecting expensive IT equipment.

1. Indirect Evaporative Cooling System

As the core heat exchange wall, the plate heat exchanger completely isolates the evaporation process from the data center air. The heat from the circulating air inside the data center is transferred to the humidified air cooled by evaporation outside, making it one of the most mainstream green cooling solutions currently available.

2. Heat Recovery System

Using plate heat exchangers transforms the data center from an "energy consumer" into an "energy hub," efficiently exchanging heat from the data center's cooling water loop to a separate, independent hot water heating loop. This improves overall energy efficiency and reduces carbon emissions.

3. Hybrid Cooling System

Modern data centers rarely employ a single cooling mode. In mechanical refrigeration mode, plate heat exchangers act as pre-coolers, utilizing outdoor low temperatures to pre-cool the return water before it enters the chiller unit, significantly reducing the chiller unit's load and energy consumption. In some designs, the plate heat exchanger's natural cooling loop and the chiller unit's mechanical refrigeration loop can be connected in parallel, intelligently selecting the most energy-efficient path based on operating conditions.

As a leading global provider of high-efficiency thermal management solutions, we understand the unprecedented challenges data center cooling systems face. Choosing JINFAN is not just selecting a heat exchanger, but choosing a long-term partner to help you achieve your sustainable development goals for your data center.

Our heat exchangers reduce volume by up to 40% for the same heat exchange capacity, saving you space, making them especially suitable for retrofit projects and edge data centers.

The unique high-efficiency corrugated plate design achieves minimal heat exchange temperature difference. We offer more than just individual products; we provide system energy efficiency optimization solutions based on plate heat exchangers, achieving the lowest overall energy consumption.

For the demanding water quality and operating conditions of data centers, we standardize 316L stainless steel plates and high-performance gaskets, ensuring corrosion resistance, leak prevention, and a longer design life.

Whether it's indirect evaporative cooling systems, heat recovery systems, or hybrid cooling systems, we have mature products and integration experience proven on a large scale.

Removable for easy maintenance and inspection. We offer hundreds of plate types, multiple materials, and multiple gasket models.

Without any gaskets, the risk of leakage is eliminated. It is widely used in the highest temperature, pressure and strong corrosiveness.

Ideal for high pressure and corrosive media. We have various specifications of welded plate bundles.