Exploring the application of Plate Heat Exchangers (PHEs) in the Metal Industry. JINFAN provides efficient and durable heat exchanger solutions.

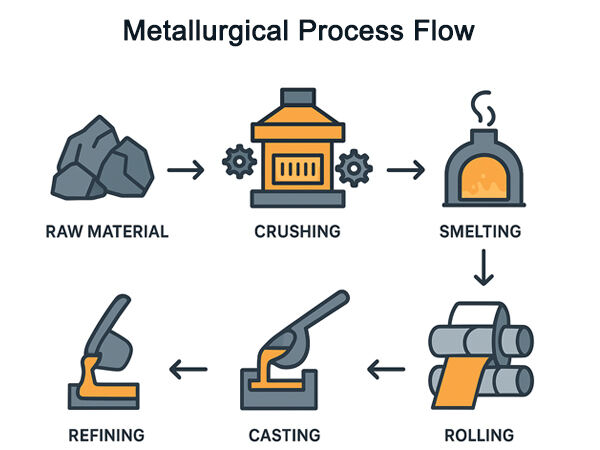

In the modern industrial system, metallic materials form the indispensable foundation of all manufacturing. The metallurgical industry is thus hailed as the “cornerstone of industry,” responsible for extracting metals or metal compounds from ores and processing them into high-performance metallic materials.

Major Categories of Metallurgical Industry

✅ Ferrous Metallurgy

Primarily refers to iron and steel smelting, the largest metallurgical branch. Its main products include pig iron, crude steel, and various steel products.

✅ Non-Ferrous Metallurgy

This encompasses the smelting of all metals except iron, chromium, and manganese, also known as “non-ferrous metallurgy.” Key products include copper ingots, aluminum ingots, lead ingots, zinc ingots, titanium alloys, and rare earth materials.

Traditional metallurgy is a high-energy-consumption, high-emission industry. Energy costs are highly susceptible to price fluctuations while simultaneously facing increasingly stringent environmental regulations and societal pressure. Against this backdrop, plate heat exchangers have gained widespread adoption in metallurgy due to their advantages: high-efficiency heat transfer, compact structure, easy cleaning, simple maintenance, and flexible scalability.

✅ Process Cooling Systems

This core application provides reliable cooling for various metallurgical equipment and processes. Plate heat exchangers are used in closed-loop cooling water systems for continuous casting machines, rolling mills, blast furnaces, hot blast stoves, electric furnaces, and converters, ensuring the safe and stable operation of critical equipment.

✅ Energy Recovery and Conservation

Metallurgical enterprises consume substantial energy. Plate heat exchangers enable recovery of residual heat from quenching water, cooling wastewater, and low-to-medium temperature flue gases. This recovered heat is utilized for preheating boiler makeup water, domestic hot water, or workshop heating, significantly reducing fuel consumption.

✅ Hydraulic and Lubrication System Cooling

Metallurgical plants operate numerous hydraulic equipment and lubrication systems where working oil temperature directly impacts operational stability. Plate heat exchangers (commonly shell-and-plate type) efficiently cool hydraulic and lubricating oils, preserving oil properties and preventing equipment failures caused by overheating.

✅ Pickling Lines and Environmental Treatment

During strip steel pickling processes, hydrochloric or sulfuric acid must be maintained at specific temperatures. Corrosion-resistant plate heat exchangers, manufactured from specialized materials, precisely control acid temperatures to ensure pickling effectiveness and product quality. Additionally, they regulate temperatures in metallurgical wastewater treatment processes.

| Recommended Type | Operating Scenario | Reason |

|---|---|---|

| Gasketed | General cooling water systems, continuous casting, air compressors | Economical, efficient, easy to maintain |

| Semi-Welded | Pickling solutions and strongly corrosive media | Welded side resists acid; gaskets do not contact corrosive fluids |

| Wide-Gap | Large-particle wastewater, slag flushing water, blast furnace scrubbing water | Excellent anti-fouling and clogging resistance |

| Wide-Gap / Semi-Welded | High-solid-content emulsions | Selection depends on contamination level |

| Semi-Welded | Water with high chloride concentration | Better corrosion resistance |

| Semi-Welded | High-temperature and high-pressure fluids | Higher temperature and pressure tolerance |

In metallurgical production, temperature control directly impacts equipment safety, product quality, and production costs. Facing harsh environments of high temperatures, pressures, and loads, you require a robust, efficient, and reliable thermal management solution. JINFAN specializes in industrial heat exchange. Our plate heat exchangers are engineered for the extreme conditions of the metallurgical industry, serving as your ideal partner to enhance competitiveness and achieve energy-saving goals.

✅ Exceptional Heat Transfer Efficiency

Our unique corrugated plate design achieves high fluid turbulence, delivering heat transfer efficiency several times greater than traditional shell-and-tube heat exchangers. This provides faster, more uniform cooling for continuous casting and rolling processes, ensuring product quality.

✅ Corrosion-Resistant & High-Pressure Design

For corrosive media in metallurgy, we offer multiple plate materials including stainless steel, titanium, titanium-palladium alloys, and Hastelloy, ensuring long-term stable operation in harsh environments.

✅ High-Efficiency Waste Heat Recovery

With an end-temperature difference design approaching 1°C, it maximizes recovery of residual heat from wastewater and quenching water. This recovered heat can be utilized for preheating boiler makeup water or heating systems, directly reducing fuel costs and delivering significant return on investment.

✅ Easy Maintenance and High Online Rate

The modular plate-frame structure eliminates the need for extensive maintenance space. Plates can be easily disassembled and cleaned, significantly reducing downtime and effectively addressing the challenge of scaling in metallurgical water systems.