How to Choose Plate Heat Exchangers for Petrochemical Plant? Explore High-Efficiency Heat Exchange Solutions for the Petrochemical Industry with JINFAN.

The petrochemical industry primarily utilizes petroleum, natural gas, and coal as raw materials, and through a series of complex chemical processing steps (catalytic cracking, hydrocracking, catalytic reforming, and thermal decomposition, etc.), produces various petrochemical products, mainly including olefins (such as ethylene, propylene, and butene) and aromatics (such as benzene, toluene, and xylene). These petrochemical products are used in almost every aspect of modern life, including packaging materials, automobile manufacturing, electronics, construction, textiles and light industry, and battery and capacitor components.

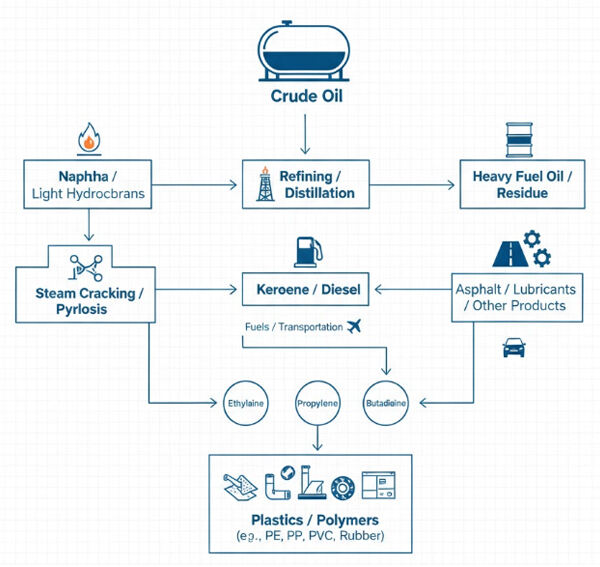

Main technological processes in the petrochemical industry

1. Crude oil processing into basic fuels and feedstocks

2. Olefin/aromatics production

3. Synthesis of final chemical products

The global petrochemical market is expected to continue growing. Petrochemical plants consume vast amounts of energy, and plate heat exchangers, with their high heat transfer efficiency, compact structure, and ease of maintenance, are widely used in key processes within petrochemical plants. Plate heat exchangers play the roles of "Heat Transporter" and "Temperature Regulator" in petrochemical plants, ensuring efficient, stable and economical production.

Preheating cryogenic fluids (such as feedstock or raw materials) using the heat from high-temperature fluids.

Cooling high-temperature reaction products, finished oils, or intermediate products to the temperature required.

Preheating feedstocks using a heat transfer medium before distillation, rectification, or reactor feeding.

Heating/cooling cooling water, circulating water, or heat transfer oils.

Unfazed by Harsh Conditions

Our Bloc Plate Heat Exchanger is better suited for high-temperature and high-pressure processes in petrochemical plants, perfectly matching the harsh conditions in heavy industries such as oil refining and gas extraction. Its all-welded structure and the use of corrosion-resistant materials (such as stainless steel) enable it to handle corrosive fluids, which is crucial in the processing of petrochemical products and intermediates.

Explore more possibilities

Selecting the appropriate plate heat exchanger in a petrochemical plant is a complex process, requiring consideration of process conditions, fluid characteristics, economics, safety, and maintenance requirements.

1. Confirm the Heat Exchanger Structure Type

In systems handling utility media (cooling water, steam) and low-corrosive/low-pressure/low-hazard process fluids (e.g., oil-water heat exchange), Gasketed PHE is recommended due to its ease of cleaning, low maintenance costs, and flexible adjustment of the heat exchange area. In systems handling high-temperature, high-pressure fluids, highly toxic, flammable, explosive, or highly corrosive media (e.g., hydrocarbons, chemical solvents), Welded PHE is preferred to eliminate the risk of gasket leakage and ensure greater safety and reliability.

2. Confirm Operating Conditions and Design Parameters

Key parameters such as flow rate, inlet and outlet temperatures, design pressure, design temperature, and allowable pressure drop need to be confirmed.

Flow rate determines the number and size of heat exchanger channels.

Inlet and outlet temperatures determine the heat exchange area.

Design pressure/temperature determines plate thickness, seal type, and material.

The allowable pressure drop determines the plate corrugation type and flow channel combination.

3. Confirm fluid characteristics and heat exchanger material

The properties of the medium directly determine the materials of the plates and seals. For highly corrosive media, special alloys (such as titanium, Hastelloy C276, 254SMO) should be selected. For fluids prone to scaling (such as those containing solid particles or with high viscosity), plate types with larger corrugation spacing should be selected. The gasket material must consider its chemical compatibility with the medium and the operating temperature.

4. Confirm plate type and quantity

The core of selection is to calculate and determine the required heat exchange area. Based on the heat exchange area, select the plate type and quantity, and determine the flow channel combination (single-channel, multi-channel, etc.) to meet the allowable pressure drop requirements of the fluid.

5. Economic and Maintenance Considerations

Prioritize long-term operating cost savings from efficient heat recovery. Choose brands and models compatible with existing factory equipment or with readily available spare parts. For fluids prone to scaling, consider whether CIP (clean-in-place) is possible, or select models that are easy to disassemble.

| Type | Core Characteristics | Typical Applications in Petrochemical Plants | Selection and Usage Rationale |

|---|---|---|---|

| Gasketed PHE |

Uses gaskets for sealing between plates, allowing for easy disassembly at any time. |

• Utility media: Cooling water, heat exchange between hot oil and water. |

Easy to maintain and clean, relatively low cost. Suitable for clean media, moderate pressure/temperature, and applications requiring periodic cleaning for fouling. |

| Semi-welded PHE | Plate pairs are welded (gasket-free seal), but gaskets are used between plate pairs. | • Refrigerant circuits: Used as evaporators or condensers in large petrochemical refrigeration units. • Hazardous or corrosive media: One side is high-hazard or corrosive fluid (welded side), and the other is a safe fluid (gasketed side). |

High safety and reliability. Welding isolates the hazardous fluid, reducing the risk of gasket leakage while retaining the dismantlability for cleaning the safe side. |

| Wide Gap PHE | The flow channel gap between plates is wider than conventional heat exchangers. | • High-viscosity fluids: Such as heavy oil, slack wax, fuel oil. • Fluids containing particles or fibers: Such as catalyst powder, slurry-like media. |

Wide channels effectively reduce clogging and fouling. Suitable for difficult-to-handle dirty fluids and high-viscosity media, ensuring continuous operation. |

| Bloc PHE | Multiple plates are welded into a solid block/core, typically fully welded. | • High-temperature and high-pressure fluids: Such as high-temperature oil-oil heat exchange, high-pressure tower overhead condensation. • Corrosive or hazardous gases. |

High pressure and temperature resistance. The welded structure provides the highest level of safety and sealing, suitable for harsh process conditions, but cleaning and maintenance are difficult. |

| Plate Condenser | A functional distinction, converting gaseous fluids into liquid form. | • Distillation/fractionation column overhead condensation: Condensing vaporized stream. • Solvent recovery: Condensing and recovering solvent vapors from process gases. |

Utilizes the high heat transfer efficiency of PHEs to achieve rapid and complete phase change, recovering valuable substances. Either fully welded or semi-welded types may be used. |

| Plate Evaporator | A functional distinction, causing liquid fluids to vaporize. | • Refrigeration systems: Vaporizing refrigerants (e.g., propane, ethylene) in petrochemical low-temperature deep-cooling units. • Reboilers: Used for heating the bottom of distillation columns to generate bottom vapors. |

Provides a high heat transfer coefficient for efficient liquid-to-gas phase change, widely used in large refrigeration circuits. |

| Corrosive PHE | Not a specific structure, but refers to the material selection of the heat exchanger. | • Acidic media treatment: Such as sour crude oil, wet CO2, acid water. • Chloride environments: Plants near seawater or media containing chloride ions. |

Selects special alloys (e.g., Titanium, Hastelloy, Super Austenitic Stainless Steel 254SMO to ensure long-term safe operation in corrosive media, preventing leakage and unscheduled shutdowns. |

Efficient, Safe, Durable, and Easy-to-maintain Heat Exchange Solutions

JINFAN has a professional team of engineers who can perform precise engineering calculations and customized selections based on the thermodynamic characteristics of the customer's specific process fluids, allowable pressure drop, and fouling thermal resistance, ensuring that equipment performance perfectly matches process requirements.

Removable for easy maintenance and inspection. We offer hundreds of plate types, multiple materials, and multiple gasket models.

Specially manufactured for phase change processes such as steam condensation, achieves extremely high heat recovery.

Specially designed and manufactured for liquid evaporation, the special flow channel design can achieve extremely high heat transfer efficiency.

Ideal for high pressure and corrosive media. We have various specifications of welded plate bundles.

The heat exchanger plate is made of a metal material with excellent corrosion resistance, handle heat exchange processes involving corrosive media

The unique wide flow channel design can easily handle media containing particles, fibers, pulp or high-viscosity liquids.

Without any gaskets, the risk of leakage is eliminated. It is widely used in the highest temperature, pressure and strong corrosiveness.