Look for ways to enhance the energy efficiency of your power plant. JINFAN Thermal Products might just have the answer you're seeking. The JINFAN plate heat exchangers are widely used options for power plants

Power generation is the starting point of the electric power industry, a process that converts natural energy sources (such as coal, water, wind, and solar energy) into the electrical energy we use daily. Whether it's heating water to produce steam by burning fuel, or utilizing wind or water power, the ultimate goal is to drive a generator. The generator is connected to a steam turbine, water turbine, or wind turbine, which converts mechanical energy into electrical energy by rotating and cutting magnetic lines of force. Plate heat exchangers (PHEs) have a wide range of crucial applications in power generation systems due to their high heat exchange efficiency, compact structure, and ease of maintenance.

High Heat Transfer Efficiency

✅ The special corrugated design on the plates generates intense turbulence in the fluid, resulting in a heat transfer coefficient far exceeding that of shell-and-tube heat exchangers.

Compact Size

✅ For the same heat transfer capacity, plate heat exchangers are only 1/3 to 1/5 the size of shell-and-tube exchangers, saving valuable space.

High Temperature Proximity

✅ Enables minimal end-point temperature differences, facilitating heat recovery and improving system efficiency.

Easy Cleaning and Maintenance

✅ Removable gasketed plate heat exchangers allow for easy opening for mechanical cleaning and maintenance.

The design, operation, and maintenance of a power plant's heat exchange system directly impact the plant's efficiency, safety, cost, and environmental impact. Optimizing the heat exchange system is a primary way to improve the overall performance of a power plant. Contact JINFAN now to discuss how to optimize your heat exchange system.

Plate heat exchangers use cooling water to remove the heat generated by the lubricating oil in large rotating equipment during operation, keeping the oil temperature within a specified safe range and preventing oil deterioration and overheating wear of the equipment.

Plate heat exchangers are used to protect the cooling medium of critical equipment from external water contamination or corrosion. The cooling water system is divided into two isolated loops. The primary circuit uses softened water to cool critical equipment. The secondary circuit uses circulating water to cool the water in the primary circuit.

In oil-fired power plants, plate type heat exchangers use steam or hot water to preheat fuel oil. This reduces the viscosity of the fuel oil, improves atomization and combustion performance, and increases boiler combustion efficiency.

In large condensing power plants, plate heat exchangers are used to isolate the cooling water of the main condenser and protect the condenser tube bundles.

Plate heat exchangers are used to transfer heat from geothermal fluids (high-temperature, high-pressure groundwater or steam) to secondary working fluids (such as organic working fluids) to drive turbines to generate electricity, and are especially suitable for low-temperature geothermal sources.

Plate heat exchangers are used to cool the heat generated during hydrogen electrolysis to ensure the electrolyzer operates at optimal temperatures; they are also used for cooling fuel cell stacks and recovering waste heat from the reaction for heating, etc.

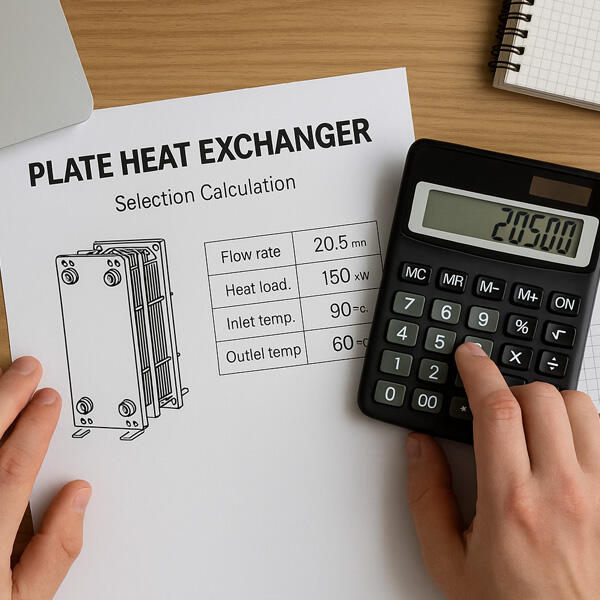

Operating Parameters

✅ Based on heat load, medium type, inlet and outlet temperatures, flow rate, operating pressure, operating temperature, and pressure drop requirements, determine the basic design of the plate heat exchanger.

Medium Type

✅ For corrosive media, select corrosion-resistant plate materials. For media prone to scaling, consider plate corrugation type, flow velocity design, and ease of subsequent cleaning and maintenance.

Plate Materials

✅ Common plate materials include stainless steel, titanium alloy, Hastelloy/254SMO, nickel alloy, etc., selected based on medium corrosivity and operating temperature and pressure.

Other Component Materials

✅ Common gasket materials include NBR, EPDM, Viton, PTFE, etc. Frame materials can be carbon steel, stainless steel, titanium alloy, etc.

| Type | Power Plant Applications | Pros | Cons |

|---|---|---|---|

| Gasketed type |

• Central Cooling Systems |

√ High efficiency |

× Risk of gasket leakage × Pressure/temperature limits × Gaskets have a limited lifespan |

| Plate Condenser | • Auxiliary steam condensation • Vacuum condensation • Geothermal • Heat pump system condensation |

√ High efficiency √ Compact size √ Easily achieves high vacuum √ Small terminal temperature difference |

× Generally not suitable for main steam condenser × May require frequent cleaning if media is fouling-prone |

| Plate Evaporator | • Geothermal • Heat pump system evaporation • Small-scale seawater desalination units |

√ High efficiency √ Compact size √ Suitable for boiling heat transfer √ Small terminal temperature difference |

× Pressure and temperature are limited × Requires special consideration if media is fouling or contains solids |

| Semi-welded | • Cooling/heating with corrosive media • Media prone to leakage • High on one side and fouling on the other |

√ Welded side resists high and strong corrosion √ Gasketed side retains the convenience |

× Higher cost compared to Gasketed × Maintenance is less flexible than Gasketed type |

| High Pressure type | • High-pressure cooling or heating in auxiliary systems • Cooling of certain special process fluids |

√ Strong pressure bearing capacity among types √ Maintains the high efficiency and compactness |

× Still has pressure limits × Usually higher cost than standard Gasketed type × Cannot replace extremely high-pressure applications |

| Wide Gap type | • Cooling/heating of media containing particulates • Fibers/high viscosity |

√ Suitable for dirty media √ Significantly reduced risk of clogging √ Lower pressure drop for high-viscosity fluids |

× Volume may be slightly larger × Efficiency may be slightly lower compared to standard gap |

| Bloc type | • Zero-leakage requirement • Certain high-pressure gas-to-gas |

√ No gaskets √ Compact, Robust, √ Extremely high tolerance √ Gasket-free maintenance |

× Capacity is non-adjustable × High initial investment cost × Cannot be dismantled for cleaning |

Higher Efficiency

Different herringbone angles, corrugation depths, and spacings affect turbulence intensity, heat transfer coefficients, and pressure drops. Different plate combinations also result in significantly different heat exchange performances. Higher flow velocities are beneficial for improving heat transfer coefficients and inhibiting fouling, but they increase pressure drops and pump energy consumption. JINFAN has years of experience in plate corrugation design and customized flow channel configurations. Based on specific media characteristics, flow rate, and temperature requirements, we precisely match the optimal corrugation geometry, optimizing the distribution and velocity of the fluid on both sides. Our equipment ensures high heat transfer coefficients while minimizing fluid resistance, maximizing overall heat exchange performance, and effectively preventing clogging and fouling.

Lower Costs

In the long-term operation of power plants, cost control of plate heat exchangers is crucial. Initial investment should consider the most cost-effective products, and maintenance costs and product costs during heat exchanger operation also need to be taken into account. JINFAN boasts a broad product range, encompassing everything from economical stainless steel gasketed types to high-performance titanium alloy fully welded types. Its unique anti-fouling corrugated design effectively extends equipment lifespan and cleaning intervals, reducing maintenance frequency and costs. Leveraging years of industry experience and mature supply chain management, JINFAN recommends the most suitable and cost-effective solutions for you.

Better Service

In power plants, environments with extremely high requirements for equipment reliability and operational efficiency, choosing a reputable plate heat exchanger supplier is crucial. JINFAN, with its years of deep cultivation and accumulation in the power industry, has become a trusted partner for numerous power plants. We have a technical team comprised of senior thermal engineers and fluid machinery experts. They are not only proficient in heat exchange processes but also deeply understand the process flows and operating characteristics of power plants. We provide one-on-one professional technical consultation to help you clarify your needs and answer your questions. We have a comprehensive after-sales service system, a professional maintenance team, and ample spare parts inventory. We ensure timely, efficient, and professional full lifecycle service support to ensure continuous and stable equipment operation and maximize the value of your equipment investment.

JINFAN is committed to providing efficient, reliable, and customized heat exchange solutions to customers worldwide. With a deep understanding of fluid thermodynamics and power plant processes, we provide robust support for your power plants, working together to achieve greater efficiency and sustainable development in the power industry.

Get in touch

Removable for easy maintenance and inspection. We offer hundreds of plate types, multiple materials, and multiple gasket models.

Specially manufactured for phase change processes such as steam condensation, achieves extremely high heat recovery.

Specially designed and manufactured for liquid evaporation, the special flow channel design can achieve extremely high heat transfer efficiency.

Aimed at energy and high-end manufacturing, it is suitable for ultra-high pressure applications such as high-pressure hydrogen production.

The unique wide flow channel design can easily handle media containing particles, fibers, pulp or high-viscosity liquids.

Without any gaskets, the risk of leakage is eliminated. It is widely used in the highest temperature, pressure and strong corrosiveness.

Ideal for high pressure and corrosive media. We have various specifications of welded plate bundles.