How to Choose Plate Heat Exchangers for the Oil and Gas Industry? Explore High-Efficiency Heat Exchange Solutions for the Oil and Gas Industry with JINFAN.

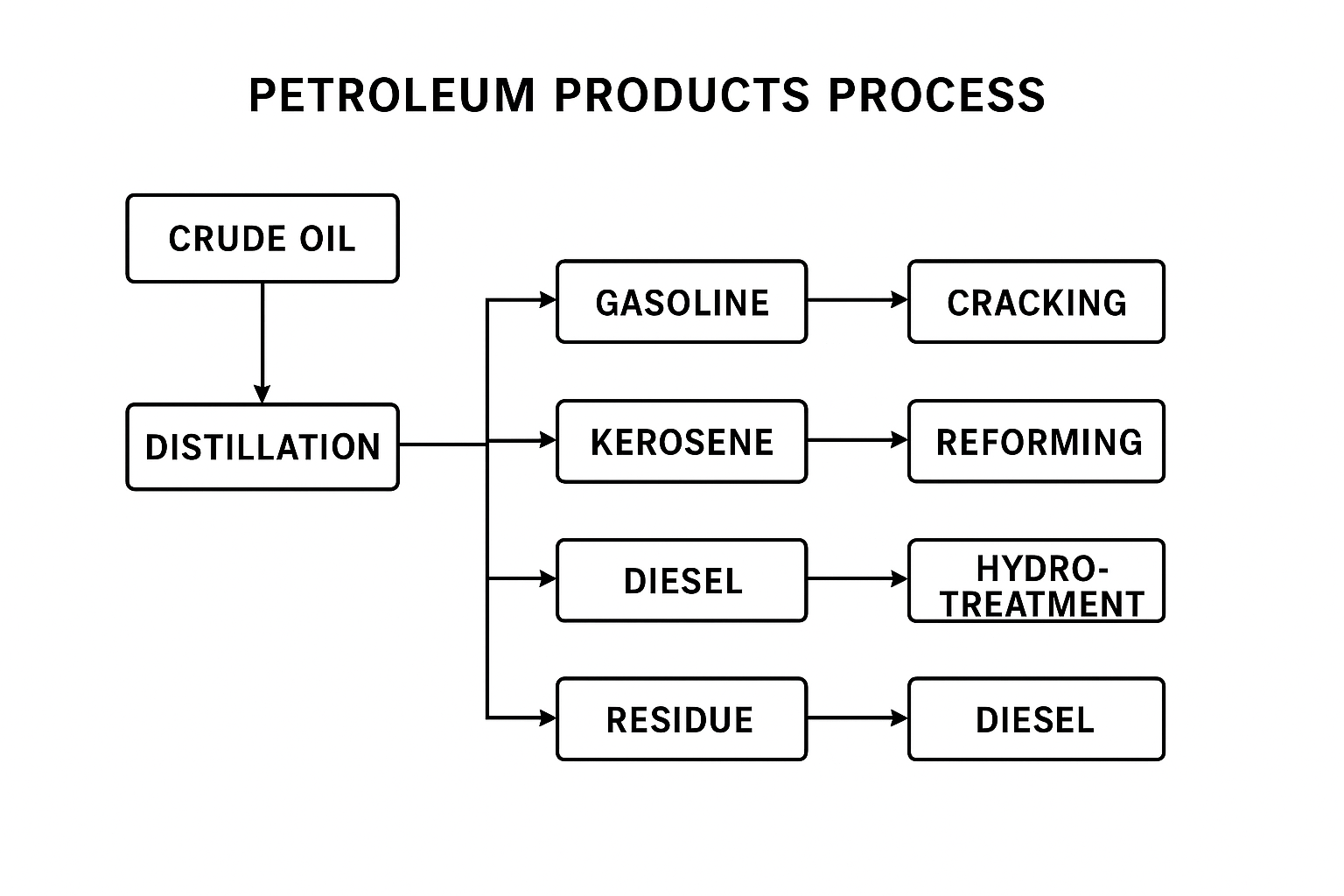

The petroleum industry encompasses a range of processes including exploration, extraction, refining, transportation, and sales of oil and natural gas. It not only provides essential transportation fuels but also serves as a valuable raw material for many chemical products and plastics. As a major force in ensuring global energy security, maximizing reliability and economic efficiency in the processing of oil and gas products is a significant challenge for companies in the petroleum industry. JINFAN, as a professional manufacturer and supplier of plate heat exchangers, maximizes the reliable operating cycle of oil and gas product extraction and processing.

The oil industry is typically divided into three main segments: exploration and production, transportation and storage, and refining, chemical processing, and sales. JINFAN has accumulated extensive experience in the oil product field, customizing solutions based on specific process flows and conditions. This allows us to better help customers overcome space constraints and achieve superior heat exchange performance. Our gasket plate heat exchanger, with its compact design, is ideal for heating and cooling the separated oil before crude oil separation. Our semi-welded plate heat exchanger and fully welded plate heat exchanger are even more suitable for optimized offshore solutions.

Get in touchWith rising energy costs, traditional profit margins for modern oil refineries are becoming increasingly narrow. JINFAN's plate heat exchangers, with higher heat transfer coefficients, maximize the recovery of process waste heat, reducing fuel and steam consumption, and increasing profit per ton of oil.

Our phe plates feature a unique corrugated design for enhanced turbulence, effectively suppressing scaling caused by high-sulfur/low-quality crude oil. Using high-quality, corrosion-resistant materials such as titanium and Hastelloy, they are better suited for acidic and high-chloride conditions, helping companies improve overall operational reliability.

JINFAN's fully welded plate heat exchangers offer extremely high pressure resistance and sealing performance, effectively eliminating the risk of fluid leakage, preventing cooling water contamination, reducing wastewater treatment costs, and complying with environmental regulations.

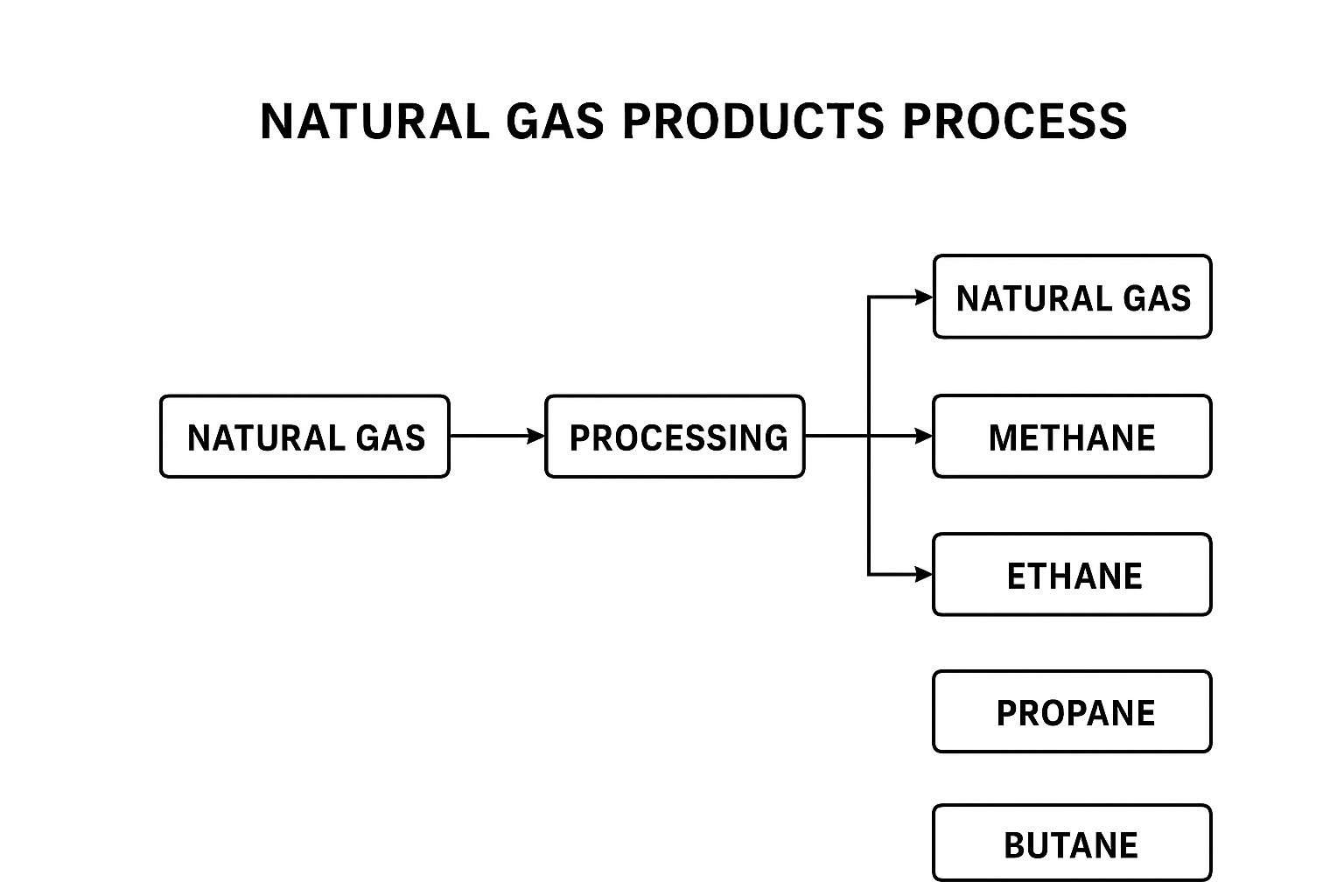

Due to the diverse geographical locations of natural gas plants and the gases being processed, each heat exchange solution presents unique challenges, making a reliable partner crucial. JINFAN possesses extensive industry experience and can help customers address these challenges. We can develop the most cost-effective heat exchange solutions for almost any process, whether onshore or offshore. Our plate shell heat exchangers are particularly suitable for demanding gas compression processes.

Get in touchHigh heat transfer coefficient, maximize heat recovery, significantly reduce external energy consumption, reduce solvent regeneration costs. improve the economic efficiency of natural gas plants.

Unique corrugated design, creates higher turbulence, effectively suppressing the deposition of particles and degradation products. Use of high-strength materials like AISI 316L and Titanium for enhanced chemical resistance, ensuring continuous and stable processing.

Efficient and reliable thermal solutions are essential for optimizing oil and gas processes, reducing energy consumption, and ensuring continuous system operation. Therefore, the selection of plate heat exchangers is particularly important and places extremely high demands on the design and selection process.

In oil and gas thermal integration projects, the temperature difference may only be 3°C to 5°C, requiring the heat exchanger to have extremely high thermal efficiency. Therefore, a corrugated plate design with a high heat transfer coefficient is selected. The oil and gas industry often involves high-temperature and high-pressure conditions. Plate materials such as titanium, C276, and SMO254 are better suited to withstand high-temperature stresses. Fully welded or plate-shell designs are suitable for pressures above 20MPa and temperatures above 300°C, ensuring safety and leak-free operation.

The design should consider selecting more corrosion-resistant materials. Crude oil, heavy oil, oil slurry containing particles, and unclean cooling water easily form fouling layers on heat transfer surfaces. JINFAN's wide flow channel design further prevents clogging. High-viscosity oils (such as residual oil) have greater pressure drops. In steam condensation/fluid flashing conditions, asymmetrical flow channels or plate-and-shell structures are used to better handle gas-liquid two-phase flow and avoid the empty tower effect.

All-welded plate heat exchangers eliminate the risk of gasket leakage, making them safer, especially when handling toxic or flammable media, but they are more expensive. For low-pressure processes, such as lubricating oil cooling, gasket plate heat exchangers can be used. Gasket materials in the oil and gas industry must be high-temperature resistant, oil-resistant, and corrosion-resistant (Viton, FFKM).

Refinery unit loads often fluctuate; plate heat exchanger design must ensure stable performance and fluid distribution under both rated and minimum loads. The design should incorporate fouling factor prediction to determine cleaning cycles; removable designs can significantly reduce maintenance downtime and lower operating costs.

| Type | Oil & Gas Industry Key Applications | Pros (Advantages) | Cons (Limitations) |

|---|---|---|---|

| Gasketed Type |

• Crude Oil Separation Pre-heating/Cooling |

√ Easy to dismantle for cleaning & inspection |

× Pressure/temperature limits × Risk of gasket leakage × Gaskets require periodic replacement |

| Plate Condenser | • Vapors/Solvent Recovery and Condensation in Gas Processing Plants • Auxiliary Steam Condensation in Refineries • Distillation Tower Condensation |

√ Optimized for two-phase processes √ Extremely high heat transfer coefficient for phase change √ Compact size for installation |

× Requires special consideration for large vapor volumes or high fouling potential × Not suitable for direct corrosive process fluids |

| Plate Evaporator | • Small-scale Wastewater Treatment Evaporation • Concentration Units in Chemical Processing • Specialized Refrigeration Cycles |

√ High efficiency in boiling heat transfer √ Compact size √ Suitable for low terminal temperature difference applications |

× Pressure and temperature are limited × Fouling or solid content in the media requires careful design |

| Semi-welded Type | • High-pressure/corrosive heat recovery • Refrigeration duties • High-pressure duties in offshore solutions |

√ Safety: Welded channel eliminates gasket risk on the process/corrosive side √ Maintainability: Gasketed side allows disassembly for mechanical cleaning √ Superior pressure resistance compared to fully Gasketed |

× Higher cost than the fully Gasketed type × Limited maintenance flexibility compared to fully Gasketed |

| High Pressure Type | • Ultra-high pressure heating or cooling • High-pressure Hydrogen Production Cooling |

√ Strong pressure bearing capacity √ Maintains the high efficiency and compactness of PHEs |

× High initial investment cost × Limited material choices for plate strength |

| Wide Gap Type | • Viscous fluid heating/cooling • Handling media with particulates or fibers |

√ Significantly reduced risk of clogging and fouling |

× Efficiency may be slightly lower than standard gap PHEs × Volume may be slightly larger than standard gap PHEs |

| Bloc/Welded Type | • Highest pressure/temperature processes • Processes requiring absolute zero-leakage isolation • Gas-to-Gas or Gas-to-Liquid heat exchange |

√ **Ultimate Safety: No gaskets, eliminating all leakage risks √ Extremely high tolerance for pressure, temperature, and corrosion √ Compact and Robust design |

× Cannot be dismantled for cleaning or inspection × High initial investment cost × Capacity is non-adjustable after manufacturing |

✅ Ultimate Energy Efficiency and Cost Control

In refineries and gas processing plants, our plate heat exchangers feature a unique design that achieves extremely high heat transfer coefficients, directly and significantly reducing energy consumption and boosting profit margins. Our equipment operates stably with minimal end-point temperature differences, helping customers capture low-temperature heat energy, maximizing heat recovery and pushing the plant's energy efficiency to the highest industry standards.

✅ Superior Reliability and System Adaptability

We offer a full range of corrosion-resistant materials (such as titanium and Hastelloy) and specially designed wide-channel plates, reducing efficiency degradation and unplanned downtime risks caused by fouling. Our fully welded and plate-shell designs meet the highest industry standards, eliminating gasket leakage risks and ensuring absolute isolation between process media and cooling water systems, guaranteeing environmental safety and downstream product purity.

✅ Optimized Maintenance and Minimized Downtime

Our removable and plate-shell heat exchangers are easy to maintain, allowing for plate inspection and cleaning without complex hoisting. This reduces heat exchanger maintenance time from days to hours, significantly improving the plant's annual availability. The compact design of plate heat exchangers makes them perfect for space-constrained offshore platforms, allowing customers to maximize heat exchange capacity without increasing their footprint.

Removable for easy maintenance and inspection. We offer hundreds of plate types, multiple materials, and multiple gasket models.

Specially manufactured for phase change processes such as steam condensation, achieves extremely high heat recovery.

Specially designed and manufactured for liquid evaporation, the special flow channel design can achieve extremely high heat transfer efficiency.

Aimed at energy and high-end manufacturing, it is suitable for ultra-high pressure applications such as high-pressure hydrogen production.

The unique wide flow channel design can easily handle media containing particles, fibers, pulp or high-viscosity liquids.

Without any gaskets, the risk of leakage is eliminated. It is widely used in the highest temperature, pressure and strong corrosiveness.

Ideal for high pressure and corrosive media. We have various specifications of welded plate bundles.