With 30+ years of plate heat exchanger production and R&D experience, JINFAN is committed to developing optimized and continuous process flow for your application. Our team is experienced & knowledgeable practitioners of the heat exchanger industry. We provide customized solutions for industrial users to better achieve heat transfer and energy saving. <p><strong>Learn more about JINFAN PHE's solution to make better choices.</strong></p>

JINFAN Plate Heat Exchangers (PHEs) facilitate industrial waste heat recovery. Inquire now to effectively capture waste heat and reduce operating costs.

How to Choose Plate Heat Exchangers for Petrochemical Plant? Explore High-Efficiency Heat Exchange Solutions for the Petrochemical Industry with JINFAN.

Exploring the application of Plate Heat Exchangers (PHEs) in the Metal Industry. JINFAN provides efficient and durable heat exchanger solutions.

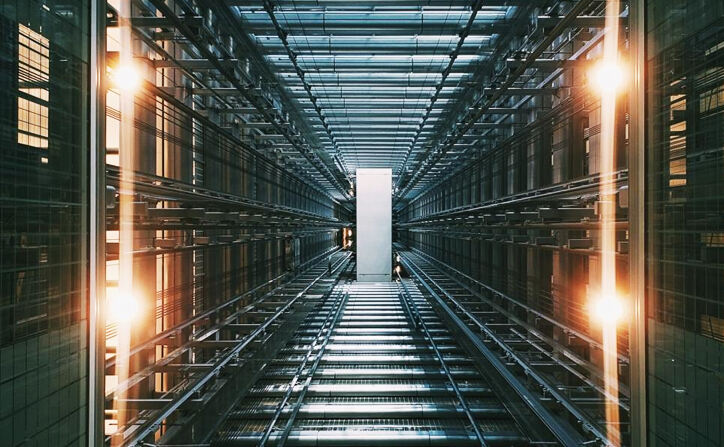

Jinfan plate type heat exchangers offer efficient and compact heat exchange solutions, helping Data Centers achieve precise temperature control.

Look for ways to enhance the energy efficiency of your power plant. JINFAN Thermal Products might just have the answer you're seeking. The JINFAN plate heat exchangers are widely used options for power plants

Learn how our plate heat exchangers provide ultimate purity, precise temperature control, and zero cross-contamination protection in biologics production.

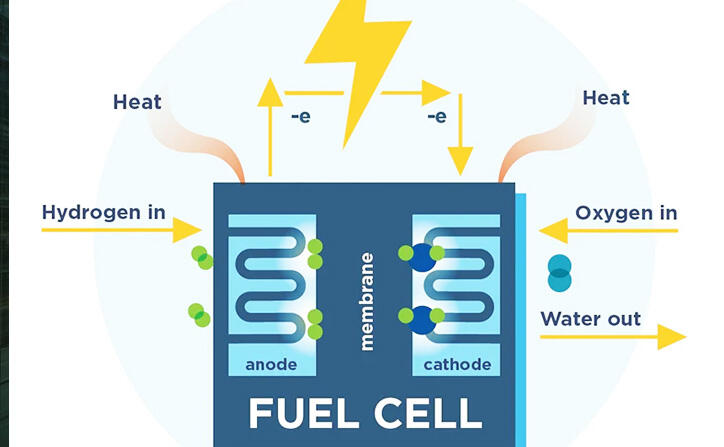

Alkaline hydrogen electrolyzer is an important supporting technology for hydrogen fuel cell systems. By producing clean, renewable hydrogen, they enable applications across a wide range of sectors including transportation, power generation and energy...

Ammonia has been known for more than 200 years. The production of significant quantities of ammonia using the cyanamide process did not occur until the early 20th century. Ammonia production is a vital industrial process that involves the synthesis o...